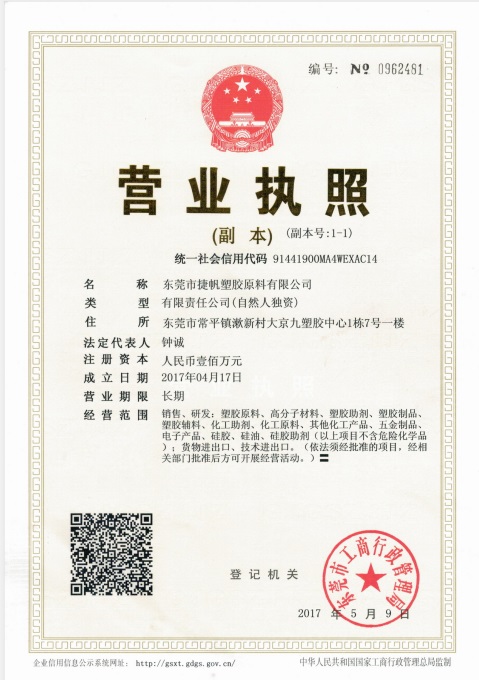

--东莞市捷帆塑胶原料有限公司--

--Dongguan Jiefan plastic material Co Ltd--

提供-韩国晓星PP J842 Topilene J842

东莞捷帆塑胶原料公司成立以来,我公司就对广大客户提供超高的服务态度品质,我们将塑胶原料做为根本中心,宗旨就是客户就是lord,也是我们的Family,我们以全心全意为广大客户们***好的服务!我公司的聚丙烯PP乃是我公司主打的通用型塑料,聚丙烯它是一种No odor、Odorless、No poison的一种高性能高结晶型聚合物,另外我们有额外的***技术人员为你解答聚丙烯成型和加工难题等方面问题。我们将还提供另种聚丙烯PP(高硬度PP、韧性PP、导电PP、阻燃PP等)。我公司的塑料货源充足(adequate)、稳定(Stable)、品种多(Many varieties),另外我们是从自家的仓库里本人提货,所以请各位大可放心质量。

At present, polypropylene PP is the lightest plastic among all plastics, especially its density is only 0.90-0.91g/cm3, which is amazing. Is the shrinkage of plastic better or ***aller? In fact, the shrinkage of plastic is too large to control the actual size of the product, which will result in low precision of the product. Therefore, polypropylene PP has good molding performance, but its shrinkage rate is too large, which leads to the problem that thick wall products are easy to sag. Polypropylene PP has high crystallinity in mechanical properties, high value in strength and hardness, and higher elasticity than HDPE, but it is far lower than HDPE at low temperature and room temperature. The most important thing to know about the mechanical properties of polypropylene PP is that its bending fatigue resistance is the best, which is exactly how polypropylene PP can withstand 7x107 times of open and close bending, so as to ensure that there will be no damage trace, but polypropylene PP cannot guarantee better with PA nylon under lubrication, but the dry friction coefficient of polypropylene PP is close to that of nylon. Polypropylene PP has good heat resistance, can be sterilized and sterilized under the condition of products above 100 ℃, and will not deform under 150 ℃, provided that polypropylene PP can not be exerted without external force. The cold resistance and polyethylene of polypropylene PP are far from enough, and PP will h***e ***ious embrittlement when it is lower than - 35 ℃. In some aspects, the performance of polypropylene PP is still insufficient compared with other plastics. As the saying goes, the strength is stronger than the strength. Judging from the current plastic Market situation, polypropylene PP is relatively competitive. Polypropylene PP has a very high dielectric coefficient, so its insulation performance will not be affected by humidity. Therefore, it can be used as thermal electrical insulation products such as insulation tape, electrical board, insulation fast bar paper. The chemical stability of polypropylene PP is excellent, but except for concentrated nitric acid and concentrated sulfuric acid, they are stable for other reagents. Chlorinated hydrocarbon and aromatic hydrocarbon h***e great influence on polypropylene PP, which can make polypropylene PP swell and soften, but its anti-corrosion performance is very good. UV has a great influence on PP, which makes PP aging rapidly. Only adding dilaurate thiopropionate, zinc oxide, opal filler and carbon black can improve the aging resistance of PP. carbon black can not only improve the aging resistance of PP, but also improve the light resistance of PP.

聚丙烯PP在成型期间它的接受适应能力很强,像普遍的注塑机可使用。聚丙烯PP在制品当中如想要更好的制品美观,可以选择着色剂来增加产品的美观,而且还能改善在制品过程中某些性能。前面我们说到碳黑可以改善聚丙烯PP的耐光性能,***为弊端的一点如果选择不恰当的话会造成对制品危害,比如酞菁系颜料骊聚丙烯的老化在前期有***作用,随着时间的不断增长会导致制品的老化,所以在使用时仔细选择合适的。折叠性能方面上聚丙烯PP被制作许多铰链的制品,但是在模具的设计时候它的折叠性能在很大的程度上取决于模具结构的合理性,所以我们需要注意模具设计的好坏。说到聚丙烯PP在制品中需要注意那些方面,我们就来说道聚丙烯PP它到底能制作什么产品?***成型制品目前是聚丙烯PP应用***大的,***成型是将塑料放在***机里面熔融,然后再将柱塞或者螺杆推力的作用下进入模具,***后使用冷却来得到制品。聚丙烯PP无非就是在挤出制品、***成型制品、热成型制品中领域***大,在***成型制品当中聚丙烯PP所制品有手提箱、挡泥板、家用电器部件、干燥机通风管、通风管、仪表盘、一次性针筒、洗衣机框架、剪草机等日用家具和消费品等,目前聚丙烯PP在家电行业中占据非常不错的应用成绩,在***各地上,中国已经成为在***世界当中家用电器的***生产中心,而且在中国还有着许多生产企业。现在我国的家电技术发展已经更为突出,产品的品种也越来越多样化,我国的传统家电从小型化到大型化这两个方向***发展,随着时间的流逝新产品不断的降临到家家户户以及市场当中。我们回到前面部分,聚丙烯PP在挤出制品当中能制作聚丙烯薄膜也能制作出聚丙烯纤维这两种物质,其中聚丙烯纤维它可以纺丝制成纤维也可以叫做丙纶,这样就能额外的用于到服装和家具市场上。另外这两种物质又能给聚丙烯PP又添加了新的改善,它的透明度和强度得到大幅度提高。聚丙烯PP也能可以用作一次性容器,比如饮水杯、热罐装饮料瓶等。

Polypropylene PP has other classification, homopolymer PP, random PP and block copolymerized PP, which are divided into three categories. Each kind of polypropylene PP has different properties and different applicati***. The reason why the impact property of PP is not so good is that its crystallinity is too high, but its molecular chain regularity is still very high. In order to improve the toughness of PP, the blending of PE and EPDM was used. Generally speaking, PP is poor in impact resistance, dimensional stability, toughness, aging and thermal stability in the long term. At present, homopolymer PP can only be used in packaging paper film, folder, brush, packing belt, household products, woven bags, blow bottles, etc. Due to the lack of material impact, hydrostatic pressure resistance, processing and heat and oxygen aging, the random addition of ethylene reduces the crystallinity and melting point of the random copolymerized polypropylene. The more random the distribution of ethylene monomer in the propylene molecular chain, the more significant the performance of the polypropylene will change. From the comprehensive view of random copolymerized polypropylene, its rigidity, strength and dimensional stability are good, especially its low-temperature toughness, transparency, glossiness and heat resistance are good. At present, random copolymerized polypropylene can be used in many fields, such as packaging paper film, drop bottles in hospitals, disposable syringes, household products in furniture market and pipes in building materials. Block copolymerized polypropylene is a kind of impact resistant polypropylene. Its rigidity is very good, so it improves its impact strength. Originally, block copolymerized polypropylene has better impact strength, but its rigidity also improves its impact strength. However, block copolymerized polypropylene is very poor in glossiness and transparency, so it can only be used in sports equipment, luggage, battery box and baby carriage. From these three different kinds of polypropylene, we can see that the strength of homopolypropylene is better, which is suitable for electrical appliances, household products and packaging paper film. The overall comprehensive performance of random copolymerized polypropylene is good, which is suitable for packaging, medical treatment and household use. The block copolymerized polypropylene is rigid, has good impact strength, and is suitable for household products and electronic ***all products. These three different kinds of polypropylene are suitable for household products and electronic ***all products Polypropylene has its own merits. It is emphasized that the strength of copolymer type is higher than that of homopolymer type! However, due to crystallization, the shrinkage of PP is quite high.

With the development of science and technology, there are many ways to produce polypropylene PP. Polypropylene PP was born in Italy in 1954. It was successfully produced by polymerization of propylene as raw material. At that time, the birth of polypropylene PP established the theory of directional polymerization. According to the research results in 1957, the world's first set of 6000t / a batch polypropylene industrial production equipment. Polypropylene PP can be divided into slurry method, gas-phase method and liquid-phase bulk method. Slurry method is polymerized, which is the earliest generation before, and its specific is diluent polymerization. Gas phase polymerization is carried out under certain conditi***. Gas phase polymerization is superior to slurry and liquid phase bulk polymerization. At present, gas phase polymerization is developing rapidly. At present, the development and application of polypropylene PP are more and more extensive. Many building materials in our lives h***e polypropylene PP accompanied. Polypropylene PP has good performance and wide application, but it is one of the optional plastics. Its mechanical properties and chemical properties play an excellent quality, but some properties are still slightly inadequate. There are many molding methods on the molding performance of polypropylene PP, familiar with blow molding, injection molding, extrusion, coating, machining, rotary molding, solution welding, foaming, electroplating, vacuum thermoforming, etc., which can be sprayed on the metal surface. Generally, the melt mass flow rate of polypropylene PP for injection is 3-4.5g/10min, some of which can reach 20g / 10min, and its moisture absorption is ***all, only 0.01%. Therefore, it is only necessary to preheat the material in the general blast oven at 80-100 ℃ before molding. As polypropylene PP will decompose and carbonize when contacting with metal wall for a long time, we need to pay attention not to use it to stay in the barrel for a long time. In order to facilitate plasticization, it is better to lengthen the shunting shuttle. If the injection cycle is to be shortened, the injection temperature can be increased appropriately to the extent that serious degradation does not occur. It is very important to choose the proper temperature in injection molding, because PP molecules are prone to orientation, which will produce strain and reduce impact strength, and orientation phenomenon is most likely to occur in low temperature and high pressure injection, so the temperature cannot be too low. The mold temperature should be about 80 ℃, not less than 50 ℃, otherwise, the surface gloss of the molded products is poor, or there are defects such as melting marks, etc., but too high mold temperature will cause warpage of the products. The second processing performance of polypropylene PP is particularly good. Its printing performance is better than that of polyethylene. Photographic convex plate, rubber plate, flat conc***e plate and other printing methods can be used. In order to obtain better heat resistance, oil resistance, water resistance and other requirements, it must be printed after corona discharge treatment.