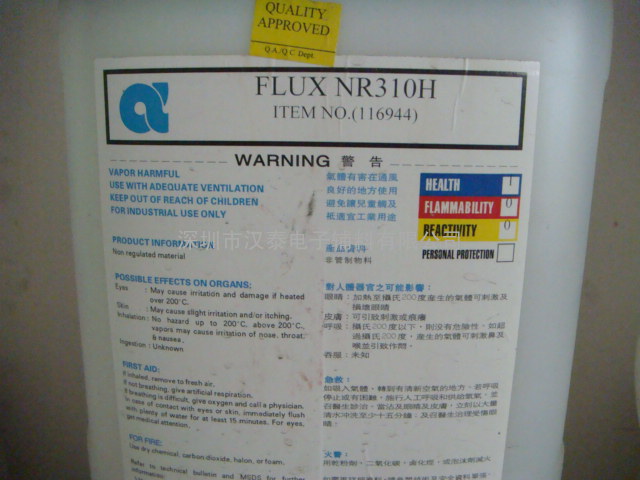

ALPHA NR310B无挥发免洗助焊剂

ALPHA NR310B (formerly 9252) was specifically developed to eliminate the tendency for solderballing and solder bridging - the two defects which are normally associated with the use of the chip w***e. Of all low solids no-clean fluxes which meet Bellcore requirements, ALPHA NR310B exhibits the lowest tendency for solderball generation over a wide variety of solder

masks. ALPHA NR310B should be c***idered for use by any assembler who has board designs which are sensitive to solder bridging, performs pin testing, and whose specification requires an extremely low frequency of solder balls.

GENERAL DESCRIPTION

ALPHA NR310B is a VOC-free, halide-free, rosin/resin-free, low solids, no-clean flux. It is formulated with a proprietary mixture of organic activators which deliver excellent wetting and top-side hole fill. Several proprietary additives are also formulated into NR310 which act to reduce the surface tension between the solder mask and the solder; thereby, dramatically reducing the tendency of solderball generation. The formulation of ALPHA NR310B is also designed to be more thermally stable; thereby, reducing the occurrence of solder bridging. Alpha NR310B meets the requirements of Bellcore NWT-000078, Issue 3.

FEATURES & BENEFITS

• VOC-free to help meet air quality regulati***.

• Excellent wetting for exceptional hole-fill even with organically coated bare copper boa***.

• Thermally stable activators provide the lowest solder bridging in a low solids, no-clean flux.

• Reduces the surface tension between solder mask and solder to provide the lowest solderball frequency of any low solids, no-clean flux.

• Very low level of non-tacky residue to reduce interference with pin testing and exhibit no visible residue.

APPLICATION GUIDELINES

PREPARATION - In order to maintain c***istent soldering performance and electrical reliability, it is important to begin the process with circuit boa*** and components that meet established requirements for solderability and ionic cleanliness. It is suggested that assemblers establish specificati*** on these items with their suppliers and that suppliers provide Certificates of Analysis with shipments and/or assemblers perform incoming inspection. A common specification for the ionic cleanliness of incoming boa*** and components is 5µg/in2 maximum, as measured by an Omegameter with heated solution.

Care should be taken in handling the circuit boa*** throughout the process. Boa*** should always be held at the edges. The use of clean, lint-free gloves is also recommended.

Conveyors, fingers and pallets should be cleaned. Bioact SC-10 Solvent Cleaner has been found to be very useful for these cleaning applicati***.

FLUX APPLICATION – ALPHA NR310B is formulated to be applied by spray or by w***e methods. When spray fluxing, the uniformity of the coating can be visually checked by running a piece of cardboard over the spray fluxer or by processing a board-sized piece of tempered glass through

the spray and then through the preheat section.

STORAGE TEMPERATURE

The storage temperature for ALPHA NR310B is 0 - 25°C to prevent phase separation. Keep from freezing.

|

Physical Properties

|

Typical Values

|

Parameters/Test Method

|

Typical Values

|

|

Appearance

|

Clear, Colorless Liquid

|

pH

|

2.6

|

|

Solids Content, wt/wt

|

3.0

|

Recommended Thinner

|

DI Water

|

|

Specific Gr***ity @ 25°C (77°C)

|

1.011 &plu***n; 0.003

|

Shelf Life

|

18 months

|

|

Acid Number (mg KOH/g) Container

|

27.0 &plu***n; 1.5

|

Size ***ailability

|

1, 5 and 55 Gal.

|

|

Flash Point (T.C.C.)

|

NONE

|

IPC J-STD-004 Designation

|

ORL0

|

汉泰电子辅料有限公司是大陆地区***早从事***T工艺研究与制作的贸易商之一。公司具有多年电子行业从业经验,拥有一支高素质的***技术团队,专注服务于***T和PCB工艺制造焊接材料领域,主营阿尔法助焊剂、阿尔法锡膏、千住锡膏、阿米特锡膏、减摩锡膏、KOKI锡膏、铟泰锡膏、田村锡膏、***T贴片红胶、富士红胶、乐泰胶水、锡丝、锡条等***T焊接材料,欢迎来电咨询洽谈,我们将竭诚为您服务。

更多产品信息请登录http://