ALPHA 373水溶性助焊剂

NEUTRAL WATER-SOLUBLE FLUX

DESCRIPTION

ALPHA Neutral Flux 373 is a water removable liquid soldering flux used in the mass soldering of printed circuit boa***. The organic activating systems in ALPHA neutral fluxes h***e a neutral pH at room temperature and become activated with elevated temperatures of the soldering process. ALPHA Neutral Flux 373 formulation provides a broad preheat range, low ***oke, low odor and does not foam in cleaning systems using soft or deionized water.

APPLICATION

Primarily for foam application and conveyorized soldering, ALPHA Neutral Flux 373 can be spray, dip, w***e or brush applied. Flux applicators and reservoir should be plastic or titanium only.

Flux coated surfaces should be preheated to provide optimum wicking and solder joint formation. The degree of preheat is dependent on many variables, such as conveyor speed, type of components and substrates. Entering the solder w***e with a topside temperature in the 170-200°F range is typical.

CONTROL

The foam applicators should be supplied with compressed air, free of oil and water. Maintain flux fluid level sufficiently above the aerator stone to produce adequate foam height. Adjust air pressure to produce optimum height with foam c***isting of ***all uniform bubbles. During use, the specific gr***ity of the flux should be checked periodically. This can be accomplished with a hydrometer, i.e., ALPHA Specific Gr***ity Kit (EQ030). Evaporated solvent should be

replenished by the addition of flux thinner. In time, debris and other contaminants will accumulate in the flux. For c***istent soldering performance, replace flux periodically. After dumping used flux, the reservoir and aerator stone should be thoroughly cleaned with flux thinner. Refill flux reservoir with fresh flux and allow a few minutes for foam to stabilize before resuming solder operation.

REMOVAL

After soldering ALPHA Neutral Flux 373, residues must be removed. Removal can be accomplished by multi-zone conveyorized in-line spray systems, automated batch spray systems (dishwashers) or multi-stage batch tank cleaning. Multiple zone in-line systems equipped with quality tap or conditioned water, an effective air knife and drying capacity, will produce MIL-P-28809 ionic cleanliness levels. ALPHA Neutralizer 2051 series or the LONCOTERGE® series of saponifiers will improve the removal of flux residues, aqueous spot masks, and other soils, particularly when cleaning in a batch system or other cleaning equipment with limited cleaning zones

PARAMETERS TYPICAL VALUES TEST METHOD

Specific Gr***ity @ 25°C 0.842 &plu***n; 0.005 5-6-80-CC

Pounds per Gallon 7.01 Calculated

Solids Content wt/wt 24% Calculated

Flash Point 56°F 6-23-81-BB

Flux Type Organic Acid (Neutral)

pH 7.0 &plu***n; 0.5 2-18-92-MP

% Chloride 2.1 &plu***n; 0.2 2-4-81-MP

Flux Thinner Thinner 425

Container Size 55 Gal 5 Gal. 1 Gal.

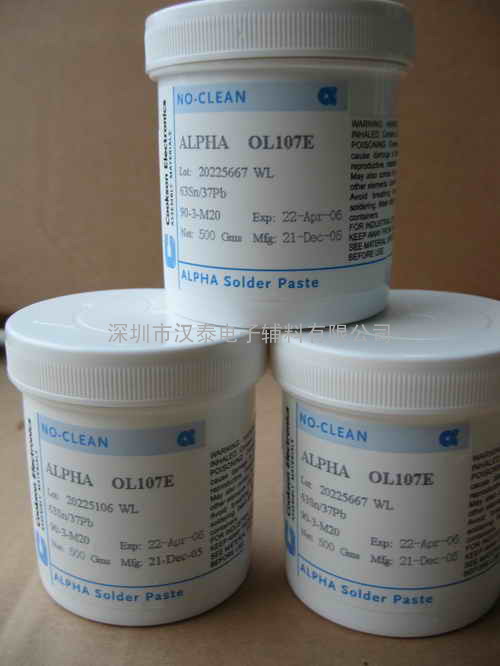

汉泰电子辅料有限公司是大陆地区***早从事***T工艺研究与制作的贸易商之一。公司具有多年电子行业从业经验,拥有一支高素质的***技术团队,专注服务于***T和PCB工艺制造焊接材料领域,主营阿尔法助焊剂、阿尔法锡膏、千住锡膏、阿米特锡膏、减摩锡膏、KOKI锡膏、铟泰锡膏、田村锡膏、***T贴片红胶、富士红胶、乐泰胶水、锡丝、锡条等***T焊接材料,欢迎来电咨询洽谈,我们将竭诚为您服务。

更多产品信息请登录http://