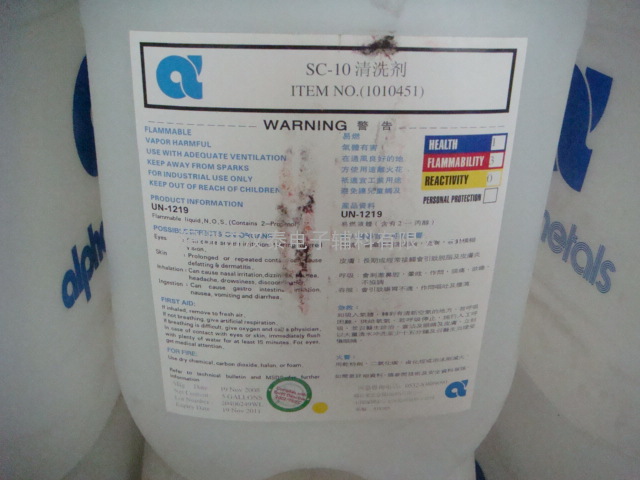

BIOACT®* SC-10

Non-Aqueous Cleaner

GENERAL DESCRIPTION

BIOACT SC-10 Cleaner is a mixture of organic solvents designed specially for non-aqueous cleaning applicati***. BIOACT SC-10 effectively removes most types of raw solder paste residues and uncured ***D adhesives. It is also effective on post-soldering flux residues and other organic contaminants associated with printed circuit board assembly. The product will evaporate completely with minimal odor. No water rinse is required.

BIOACT SC-10 is an excellent replacement for IPA in most applicati***.

FEATURES & BENEFITS

• Effective cleaner at ambient temperature. Ideal for stencil cleaning and non-aqueous batch cleaning.

• High solvency of solder paste residues. Reduces process time.

• High flux loading capacity. Longer bath life.

• Non-corrosive. Compatible with most stencil and PWA materials of c***truction.

• Fast evaporation. Reduces process time. No water rinse required.

• Effective in a wide range of applicati***. Reduces the number of chemicals required in a facility

PROCESS (Stencil/PWA Cleaning) - BIOACT SC-10 Cleaner is used at ambient temperatures to dissolve raw solder paste residues, uncured ***D adhesives, flux residues, tape residues and other oily contaminants such as fingerprints. After cleaning, stencils or assemblies can

be dried by evaporation or solvent displacement with forced air (no water rinse is required). If additional cleanliness is needed, stencils or assemblies may be rinsed with a secondary BIOACT SC-10 rinse. Bath life will depend on stencil cleanliness requirements. For PWA cleaning, refractive index and/or specific gr***ity can be used to determine rosin loading in the cleaning

solution (contact Petroferm for more information). In both stencil and PWA cleaning, the use of a secondary rinse generally will allow for longer utilization of the initial BIOACT SC-10 wash bath.

EQUIPMENT - BIOACT SC-10 Cleaner is suited for use in appropriately designed non-aqueous equipment. (As a general guideline, BIOACT SC-10 is suitable for use in most equipment which is designed to handle IPA.) This includes batch equipment by Martin Marietta (Jet Clean),

ECD, EMC and Austin American. In addition, BIOACT SC- 10 Cleaner can be recovered by batch vacuum

distillation. Contact Petroferm for recommendati*** on equipment applicati***.

MATERIALS COMPATIBILITY - The effect of BIOACT

SC- 10 Cleaner on solder paste stencils, printed wiring assemblies, electronic components and markings is comparable to that of traditional halogenated and alcohol cleaning solvents. Safe for epoxies, flex laminates and other cross-linked polymers, such as cured solder mask. Sensitive materials such as RTV silicone, polystyrene, polyurethane and some polycarbonates may be attacked after prolonged exposure to the liquid.

DISPOSAL - When it has been determined that the BIOACT SC-10 bath is no longer useful, the solution can be disposed of through fuel blending. The cost of fuel blending BIOACT SC-10 is determined by fuel volume, water content and solids content. He***y metal content should be analyzed to see if the BIOACT SC-10 waste is potentially a hazardous waste. Laidlaw Environmental

Service, Ashland Chemical Environmental Service or other reputable waste hauling and disposal companies are recommended.

PACKAGING AND STORAGE

BIOACT SC-10 is ***ailable both as bulk liquid in 1, 5 and 55 gallon containers and as pre-saturated wipes in tubs. When shipped by ground or air transportation, it is

c***idered a "flammable liquid". When stored, it is c***idered a Class II combustible liquid according to current NFPA regulati***. BIOACT SC-10 has a shelf life of 18 months from date of manufacture. (BIOACT SC-10 may still be usable beyond this date; contact Petroferm

for information on determining whether out of shelf-life product is still within specification.)

HEALTH & SAFETY

BIOACT SC-10 Cleaner is intended for use by technically trained personnel. Repeated contact with skin may cause irritation. Use standard chemicals handling procedures, including solvent resistant gloves (Nitrile, Viton or PVA) and safety glasses with side shields or chemical goggles. The use of latex gloves is not recommended for this product. Use in well ventilated areas. Please c***ult product MSDS for more information

汉泰电子辅料有限公司是大陆地区***早从事***T工艺研究与制作的贸易商之一。公司具有多年电子行业从业经验,拥有一支高素质的***技术团队,专注服务于***T和PCB工艺制造焊接材料领域,主营阿尔法助焊剂、阿尔法锡膏、千住锡膏、阿米特锡膏、减摩锡膏、KOKI锡膏、铟泰锡膏、田村锡膏、***T贴片红胶、富士红胶、乐泰胶水、锡丝、锡条等***T焊接材料,欢迎来电咨询洽谈,我们将竭诚为您服务。

更多产品信息请登录http://