| Optibelt同步带 |

| Optibelt OMEGA HL免维护同步带 |

|

详细介绍:

优点: l 高负载、超范围极限速度的高性能同步带 l 适用于高扭矩 l ***高***度和准确的同步性 l 优良的吸收冲击载荷性能 l 优化齿形降低了运行噪音 l 降低了驱动空间,降低了系统成本 l 免维护 l 耐温范围:– 30 °C – +100 °C l 传递能力为 Optibelt OMEGA的2.5倍 l 更低的轴承负荷 l 优化的防磨损性能

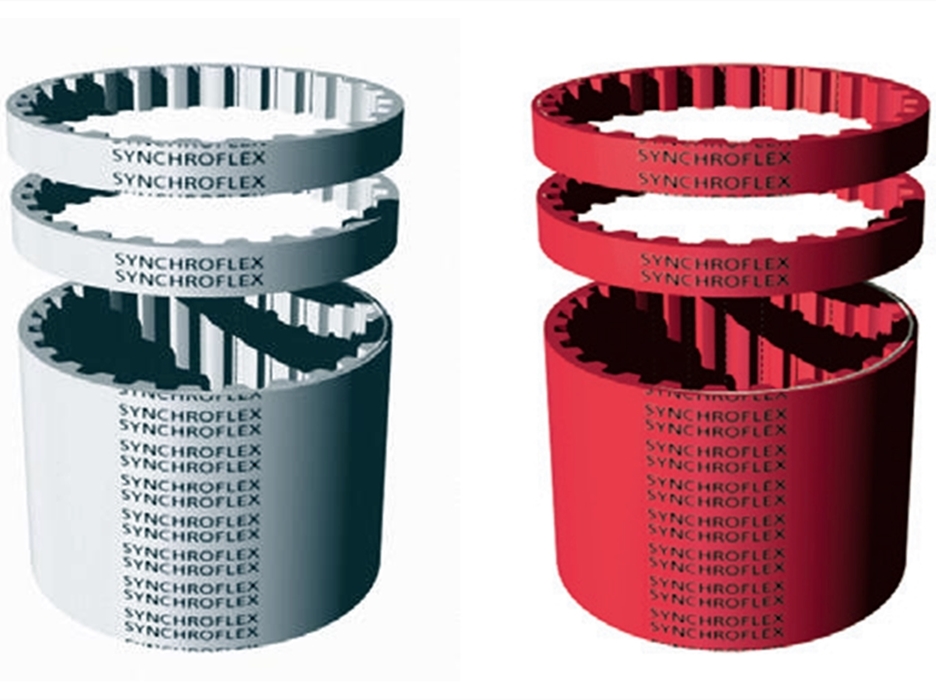

结构

背层: 和带齿材料一样,Optibelt OMEGA HL的背层是由经过芳族聚酸胺纤维加固的聚氯丁二烯制成的。因此和反向惰轮接触时耐磨损性更强,同时这种表面也会保护张力线免受环境的影响。 张力线: 和Optibelt OMEGA HP所含的玻璃纤维张力线不同的是,Optibelt OMEGA HL用的是经过实质性改良的玻璃纤维,这种张力线让皮带性能提高了25%并使其冲击载荷显著提高。 带齿: 在带齿表面的织物下,一种高强度的聚氯丁二烯化合物让受力安全地传送到张力线上,通过把芳族 聚酸胺纤维和这种化合物混合,这种材料可保证OMEGA HL齿形的高度稳定,并使每族个带 齿具有更大的切变强度。 织物: 由高强度纤维与内部化合完全粘合而成,从而加强了带齿切变强度,Optibelt OMEGA截面的设计, 以驻织物产生的***小摩擦力可保证带齿和轮齿之间更好的啮合,此外,所使用的聚酸胺织物具有极 强的抗磨损性。 应用领域: l 机械传动 l 根据实际情况,取代链条 l 输送系统 l 木材工业和造纸行业 l 纺织机械 l 园林机械

功率对比

当今的高功率传动提出来了对高质量传动带的需求:更长的使用寿命、更高的性能、更低的更换频 率、更少的材料和系统成本-有一种新型Optibelt同步带可同时满足这些要求。 它就是:Optibelt OMEGA HL=***佳传动配置与***大程度的利用 型号名称来源: O-(***佳带齿截面) M-(德国制造) E-(巨大的工作潜能) G-(总宽大大减少) A-(应用范围广) HL-(高载荷)

Optibelt OMEGA HL:设计工程师的首选

截面:8M HL, 14M HL 尺寸:288 -4578 毫米 同步轮:OMEGA HL同步带不需要任何特殊的带轮,其型号适于标准的 HTD® 和RPP® 带轮

定购示例: 同步带:Optibelt OMEGA HL1200 8M HL 20 1200 =1200毫米长度 8M HL =截面和构造 20 =20毫米带宽

|

Optibelt belt

Optibelt OMEGA HL timing belt maintenance

Details:

Optibelt common for high-performance machines with high torque and intermittent shock loads of gear, to develop this pitch was 8M and 14M belt, its design and material composition h***e been the greatest degree of improvement, which can be In the new tran***ission unit to provide maximum functional reliability and the best efficiency, Optibelt OMEGA HL timing belt tran***ission capacity than Optibelt OMEGA HP above 25%. In addition, the optimized design OMEGA HL more suitable for driving with a shock load.

Advantages:

l high-load, ultra-high performance belt speed range limit

l for high torque

l the highest precision and accuracy of the synchronization

l Excellent performance impact load absorption

l Advanced profile reduces operating noise

l reducing the drive space and reduce system cost

l Maintenance-free

l Temperature range: - 30 ° C - +100 ° C

l tran***ission capacity Optibelt OMEGA 2.5 times

l lower bearing loads

l of anti-wear performance optimization

Structure

Back layer:

And materials with the same tooth, Optibelt OMEGA HL back layer is made of aromatic polyamide through fiber reinforced polychloroprene made. Therefore, the reverse idler contact and wear resistance more, while also protecting the surface tension of this line from the environment.

Tension wire:

And Optibelt OMEGA HP contained in the glass fiber tension line is different, Optibelt OMEGA HL is the result of substantial improvement with the glass fiber, this tension to the belt line performance by 25% and significantly increase its impact loads.

With teeth:

On the surface of the fabric with a tooth under a high intensity of polychloroprene compound to be sent securely to the tension force online, through the aromatic

Polyamide fibers and mixed this compound, this material can guarantee OMEGA HL profile of highly stable, making each one with family

Tooth has a greater shear strength.

Fabric:

From high-strength fibers bonded together with internal compounds completely, thus enhancing the shear strength with teeth, Optibelt OMEGA cross-section design,

Produced in the fabric to ensure minimal friction between the belt teeth and tooth meshing better, in addition, the use of polyamide fabric has a very

Strong abrasion resistance.

Application areas:

l mechanical tran***ission

l according to the actual situation, replace the chain

l delivery system

l timber industry and paper industry

l textile machinery

l garden machinery

Power Comparison

Today's proposed high-power tran***ission belt of high-quality demands: longer life, higher performance, lower replacement frequency

Rate, less the cost of materials and systems - has a new Optibelt belt can meet these requirements.

It is: Optibelt OMEGA HL = the best drive configuration and maximum use of

Type the name of the source:

O-(the best section with teeth)

M-(Germany)

E-(great work potential)

G-(a significant reduction in the total large)

A-(wide application)

HL-(high load)

Optibelt OMEGA HL: first choice for design engineers

Section: 8M HL, 14M HL

Size: 288-4578 mm

Synchronization round: OMEGA HL timing belt does not require any special pulley, the model for the standard HTD ® and RPP ® pulleys

Order Example:

Timing: Optibelt OMEGA HL1200 8M HL 20

1200 = 1200 mm length

8M HL = cross-section and c***truction

Bandwidth of 20 = 20 mm