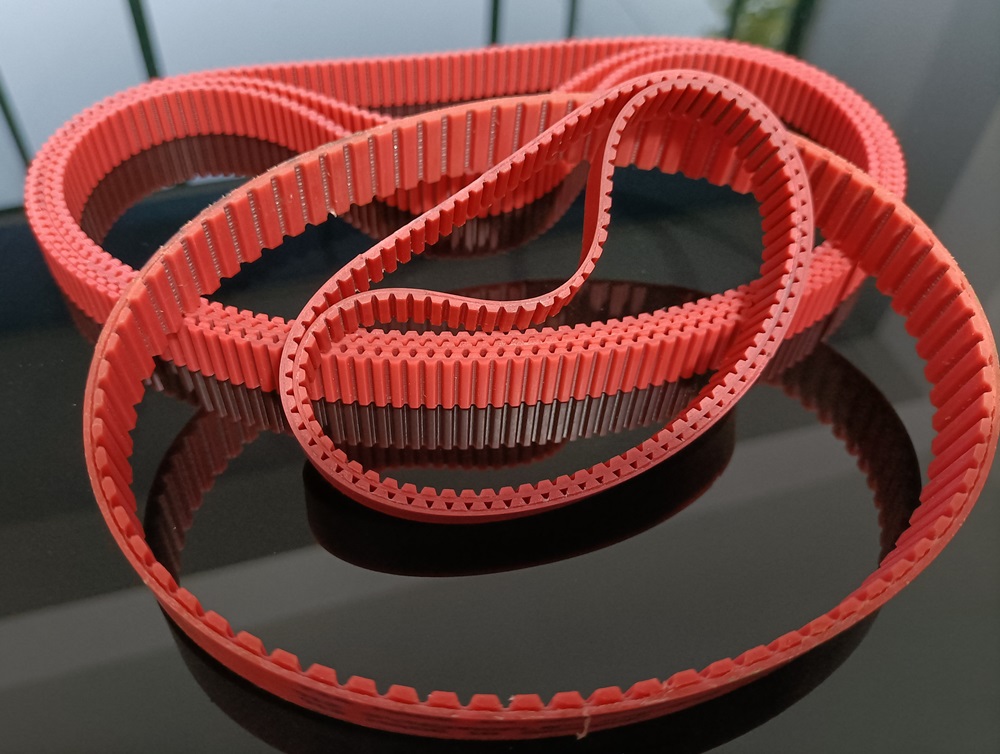

pulleys are not parallel timing belt failure.

Timing belt running on a timing belt pulleys on both sides h***e ribs and a timing belt pulleys on both sides of ribs when the two timing belt pulleys are not parallel, then the timing belt will be part of the timing belt pulleys move with no ribs, no ribs timing belt wheel in this part of the timing belt will bear all the load and may be in the running for some time to produce a concentrated wear areas. The concentration of most of the tooth surface wear, no wear elsewhere. Cracks may h***e roots in the wear areas below. Timing belt strength or tooth surface fatigue will eventually lead to premature timing belt failure. The timing belt at run time, the timing belt axle at an angle, or timing belt tooth-shaped taper problem exists in the processing load unevenly applied to the timing belt on the toothed uneven extrusion. The timing belt failure often begin to tear from the tooth root cracking, or from carrying tension the timing belt side and extended to the whole timing belt width, eventually leading to the timing belt tooth shear. Relatively large due to fiber tension, timing belt squeeze serious side may also appear ***ious wear and tear, and the timing belt may climb out of or rolled rib of the Department of timing belt pulleys.

BRECO同步带同步带轮不平行导致同步带失效

同步带运行在一个同步带轮两边都有挡边和一个同步带轮两边都没有挡边时,如果两个同步带轮不平行,那么同步带会部分向没有挡边的同步带轮移动,无挡边同步带轮中这部分同步带将会承受全部负载并且可能在运行一段时间后产生一个集中磨损区域。大部分齿面的集中磨损,其它地方没有磨损。在磨损区域下面可能会有根部裂缝。BRECO同步带强度或齿面疲劳***终都会导致同步带的过早失效。

同步带在运行时,同步带轮轴成一定角度,或同步带轮齿形在加工时存在锥度问题,由于施加在同步带上的负载不均匀,带齿之间会出现不均匀的挤压。同步带失效经常从齿根开裂处或从承载张力***大的同步带侧面开始撕裂并扩展到整个同步带宽度,***终导致同步带齿部剪切。由于纤拉力比较大,同步带挤压严重的一侧可能也会出现明显的磨损,并且同步带有可能爬出或滚到同步带轮挡边之处。

Due to improper operation caused by the timing belt bend reas***: improper storage, improper packing and timing belt installation and installation of improper operation. The run may h***e been jumping tooth timing belt in the case of low tension until it reaches an acceptable tension, a phenomenon called automatic tensioning.

Automatic tension from the timing belt pulleys round slot can be most clearly observed in the loose side of the timing belt or timing belt teeth into. When the timing belt automatic tensioner, timing belt teeth jump out of the timing belt tooth timing belt pulleys round slot until the timing belt tight side to strengthen the tension force into the timing belt pulleys round slot. Timing belt pulley wheel groove is forced to return, often resulting in dramatic timing belt and pulley contact points, the instantaneous bending, this bending will cause the timing belt wire damage. This part of the core wire injury is called a bend. Tight side tension the timing belt teeth into the pulley wheel groove, then the timing belt to skip teeth, also will produce a bending failure or timing belt tooth damage.

Timing belt into the diameter is too ***all pulley will cause the timing belt wire damage or bending failure. Pulley and back idler pulley below the stipulated minimum, timing belt and timing belt pulleys, idler wheel or by hand to the ***aller acute angle bend timing belt will cause the timing belt bending failure.

Tran***ission entry of foreign matter also make a bend timing belt, they will le***e the timing belt and timing belt pulleys to form a sharp corner, so that the timing belt wire bending. The timing belt forcibly pry tool to also make the timing belt pulleys damage. Improper use of tools (such as a screwdriver) on the timing belt after injury, the timing belt will not immediately be invalidated by the entry of foreign matter or install, but the timing belt overall life will decline. The timing belt bending failure mode manifests itself in the fracture surface wire into a straight line.

When the timing belt wire bent into a very ***all diameter, this failure mode occurs. Sharp bend will make the timing belt wire fiber bending under huge pressure and damage, so the timing belt's tensile strength decreased. The timing belt bending failure is the most common failure mode, usually associated with the timing belt operating properly, install the tension is too low, the diameter of the pulley is too ***all and there are foreign bodies inside the pulley.

BRECO同步带折曲失效原因分析

由于操作不当所引起的同步带折曲原因有:存放不当、包装不当和同步带安装前和安装时的操作不当。同步带在过低张紧力的情况下运行可能会一直跳齿直到达到可接受的张紧力,这种现象叫做自动张紧。

同步带进入直径过小的带轮时,也会导致同步带芯线受损或折曲失效。带轮和背部惰轮低于规定的***小值、同步带和同步带轮间有惰轮甚至用手以较小的锐角弯曲同步带,都会导致同步带折曲失效。