Siegling – total belting soluti***

2

Siegling Extremultus – exceptional power tran***ission

We h***e developed the Siegling Extremultus power tran***ission belt range in close co-operation with users and OEMs. As a result, it can offer a market-driven range of types that can handle all sorts of power tran***ission in every industry.

Contents

Multi-purpose, highly-efficient belts Overview of the lines A, E, P line product range 5 6 8

Different materials for the friction and top coating are combined with one of the three tension member materials – A (aramide – also truly endless) – E (polyester – also truly endless) or – P (polyamide) Producing a varied range with ideal properties for each and every application. Siegling Extremultus power tran***ission belts are durable, extremely tough, elastic, absorb vibrati*** and shocks and can be used at belt velocities of up to 100 m/s.

Compared with other power tran***ission belts, they are easy to handle, extremely efficient and h***e a high level of synchronisation accuracy. Apart from traditional pulleys, they can easily handle bevel and cone drives and drive several shafts, even in different rotational directi***.

Product range Truly endless belts 10

The properties

thin/flexible

The advantages

low power requirement, ***all pulley diameter c***tant RPM, long belf life

More information on Siegling Extremultus flat belts can be found in the following brochures:

No. 262 266 296 316 Title Wood Logistics/live roller conveyors Yarn production Siegling Extremultus Flat belts Technical Information

c***tant friction coefficient, high wear-resistance high elastic modulus

short take-up ranges, low creep good edge stability treats bearings gently, vibration-free operation

laterally stiff good damping properties

3

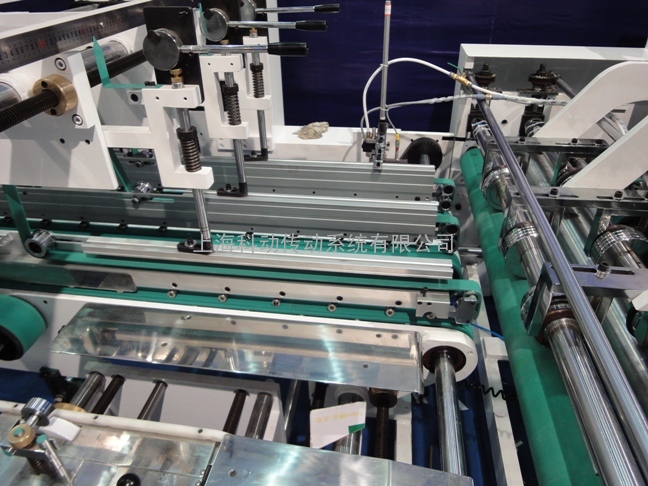

Chipper (wood manufacture), belt type GT 80 P black, width = 1000 mm, P = 1850 kW, v = 65 m/s

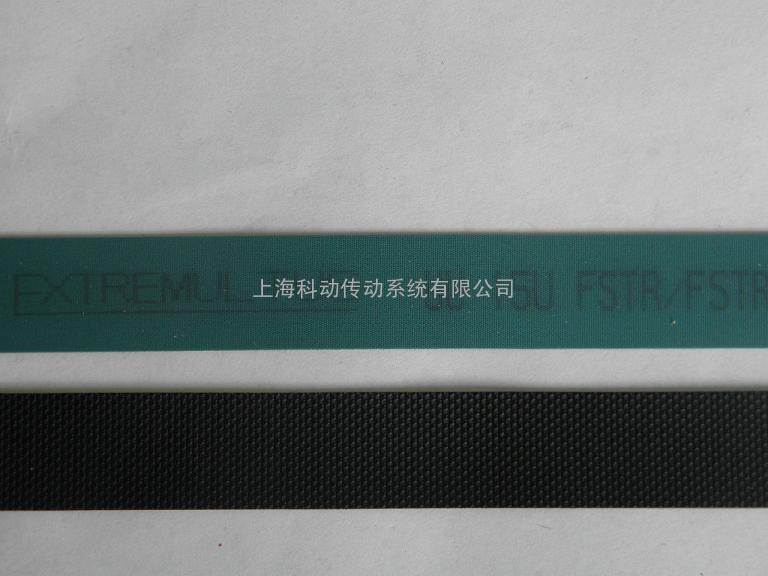

Drive (textile industry/yarn manufacture), belt type GG 20E-20 NSTR/FSTR grey/black

Live roller conveyor (logistics), belt type GG 20E-20 green

4

Multi-purpose, highly-efficient belts

In addition to other advantages, flat belts are much more efficient than V-belts. In V-belts, energy losses occur, not just due to flexing in the material, but also due to friction at the sides and other aspects associated with the belt design.

Friction on the sides at the top and bottom, internal friction losses due to hysteresis.

Higher friction losses when the V-belt pulleys are misaligned.

100 99 98 97 96 95 94 93

Flat belts

V-belts

Source: Tests carried out by the University of Gteborg German Institute for Materials Testing, Berlin Difference in length and rotational vibrati*** when V-belts are not loaded evenly.

100

Efficiency of a flat belt (top), efficiency of a V-belt (bottom). Siegling Extremultus flat belts h***e an efficiency of 98.6 %.

Classical two-pulley drive Multiple pulley drive Taper-cone drive Mule drive 5

Overview of the lines

E line

Top coating

A line

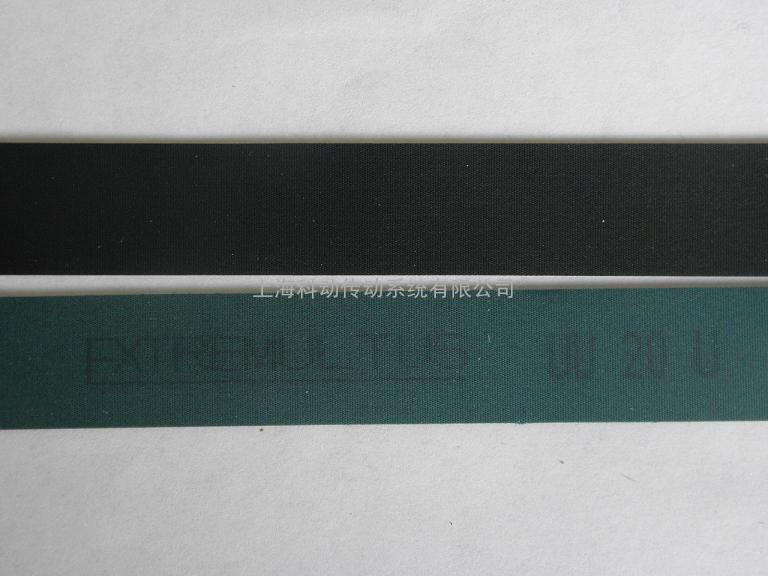

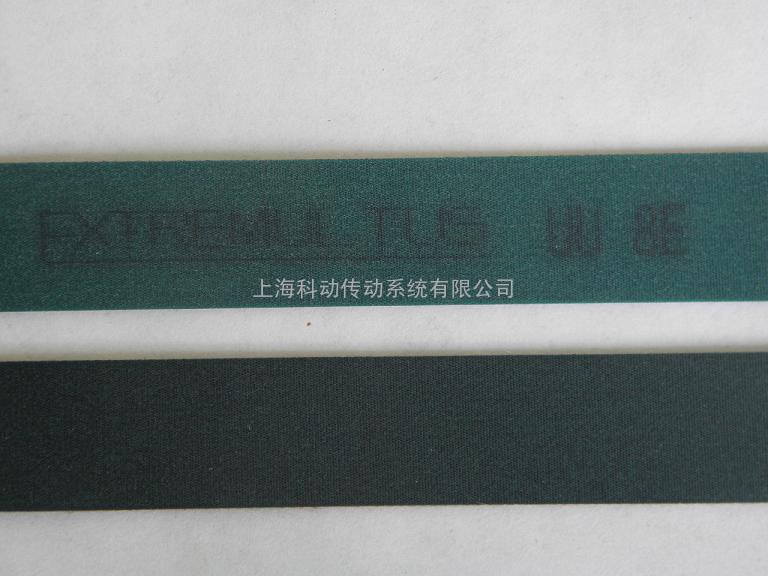

Highly wear-resistant elastomer G (black) or highly wear-resistant urethane (green) Thermoplastic tension member with highlymodular mixed fabric and aramide warp Highly wear-resistant elastomer G (grey) or highly wear-resistant urethane (green) Tran***ission of significant effective pull at low elongation

Highly wear-resistant elastomer G (grey or black) or highly wear-resistant urethane (green) Thermoplastic tension member with polyester fabric in warp and weft Highly wear-resistant elastomer G (grey or black) or highly wear-resistant urethane (green) Tran***ission of significant effective pull at low elongation 0.3 % – 2.0 % High flexibility Good Z-splice 70 x 11.5 mm without adhesives Power tran***ission belts with polyester tension members made can tran***it significant effective pull and are excellent value. They are a perfect solution for almost any application.

Tension member

Friction coating

Traction layer properties

Elongation at fitting Flexibility Damping properties Type of splice

Elastomer G: 0.3 % – 1.0 %, urethane: 0.3 % – 0.8 % High flexibility Low Z-splice 110 x 11.5 mm without adhesives Power tran***ission belts with aramide tension members are designed for high levels of specific effective pull. Aramide line belts require careful handling to ensure perfect operation.

Other factors

Friction/top layer properties

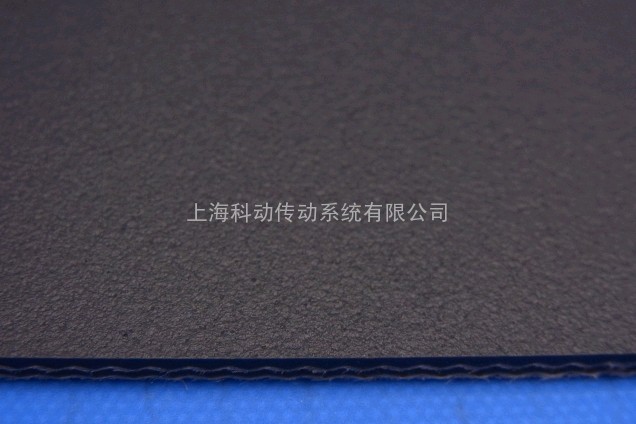

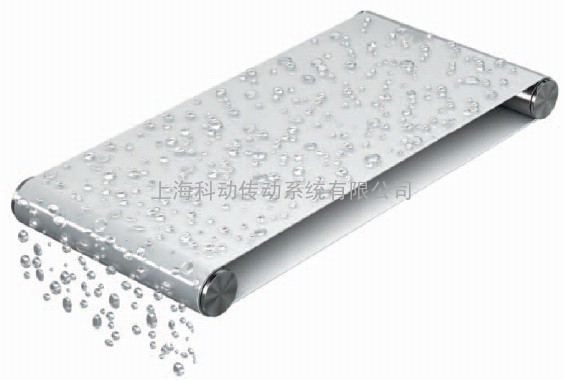

Urethane (U) The urethane friction layer U is mainly used for drives. Thanks to its low thickness, it is especially well-suited for extreme flexing stress. Elastomer G (G) The friction coating elastomer G is used for all standard drives, also wherever dust and moisture are a factor. Not recommended when oil and grease are present (e.g. oil vapour). Chrome-leather (L) The chrome-leather friction coating is used wherever oil and grease are present.

6

P line

Chrome-leather, highly wear-resistant elastomer G (black) or polyamide fabric Highly-orientated polyamide sheet

The endless line

Chrome-leather, highly wear-resistant elastomer G/Urethane (green) or polyamide fabric Truly endless polyester cord Truly endless aramide cord Chrome-leather or highly wear-resistant elastomer G/Urethane or polyamide fabric Tran***its high levels of effective pull with little elongation

Chrome-leather or highly wear-resistant elastomer G (black or grey) Tran***ission of large effective pull

1.5 % – 3.0 % Low flexibility Very good Wedge splice with adhesives Power tran***ission belts with tension member made of polyamide sheet are laterally stiff and h***e very good damping properties.

Polyester cord: 0.5 % – 1.5 %, aramide cord: 0.3 % – 1.0 % High flexibility Polyester cord: very good, aramide cord: lower No splice, as truly endless

Power tran***ission belts with truly endless polyester or aramide cord tension members require short take-up ranges, can tran***it high specific levels of effective pull and are not sensitive to fluctuati*** in ambient conditi***. Because they are very flexible and track very steadily and evenly, they are an excellent choice for high levels of power tran***ission (> 60 m/s) and multiple rotati***.

GG = elastomer friction layer on both sides (normal pattern) for power tran***ission on both sides UU = green urethane friction coating on both sides, power taken from both sides of belt. GT = elastomer friction coating on one side, for power tran***ission on one side, top coating made of polyamide fabric.

LT = chrome-leather friction coating on one side, for power tran***ission on one side, top coating made of polyamide fabric. LL = chrome-leather friction coating on both sides, for power tran***ission on both sides

7

Technical data Weight approx. [kg/m2] 1.9 2.7 3.45

Nominal effective pull approx. [N/mm belt width]**

Max. tran***ittable effective pull [N/mm belt width]

A line UU 15A-17 FSTR/FSTR green GG 25A-25 NSTR/FSTR grey/black GG 40A-32 NSTR/FSTR grey/black E line GG 8E green UU 20E-16 FSTR/FSTR green GG 20E-20 green GG 20E-20 NSTR/FSTR grey/black UU 30E-20 FSTR/FSTR green UU 30E-32 FSTR/FSTR green GG 30E-25 NSTR/FSTR grey/black GG 30E-32 FSTR/FSTR black GG 30E-32 green TG 30E-30 black/green P line LL 6P LL 10P LL 14P LL 20P LL 28P LL 40P LT 6P LT 10P LT 14P LT 20P LT 28P LT 40P LT 54P LT 65P LT 80P GG 10P-20 NSTR/FSTR grey/black GG 15P-22 NSTR/FSTR grey/black GG 20P-25 NSTR/FSTR grey/black GG 20P-30 NSTR/NSTR black GG 30P-32 NSTR/FSTR grey/black GG 30P-37 NSTR/NSTR black GT 6P black GT 10P black GT 14P black GT 20P black GT 28P black GT 40P black GT 54P black GT 80P black

995473 822130 822131

1.7 2.5 3.2

24 40 60

15 25 40

0.8 1.0 1.0

15 28 42

Shaft load at 1% elongation [N/mm belt width]

72 55 90

0.3 – 0.8 0.3 – 1.0 0.3 – 1.0

822062 822055 822052 822145 822133 822105 822126 822118 822051 822058

1.5 1.6 2.0 2.0 2.0 3.2 2.5 3.2 3.2 3.0

14 30 24 24 30 30 30 40 40 40

10 14 20 20 20 14 30 26 22 –

2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 –

10 20 20 20 30 20 30 28 22 –

8 23 23 23 28 23 30 30 23 30

0.3 – 2.0 0.3 – 2.0 0.3 – 2.0 0.3 – 2.0 0.3 – 2.0 0.3 – 2.0 0.3 – 2.0 0.3 – 2.0 0.3 – 2.0 0.3 – 2.0

1.6 1.85 2.15 2.2 2.2 3.55 2.75 3.55 3.4 3.2

800015 800016 800017 800018 800019 800020 800007 800008 800009 800010 800011 800012 800013 998059 800014 855604 855605 855606 855602 855607 855603 850044 850045 850046 850047 850048 850049 850050 850051

3.0 3.1 3.5 4.4 4.9 5.9 2.0 2.2 2.4 3.4 3.7 4.4 5.5 5.8 7.2 2.0 2.2 2.5 3.0 3.2 3.7 1.3 1.6 1.8 2.5 3.0 3.65 4.5 6.0

35 40 60 90 120 200 30 30 60 90 125 200 300 400 400 30 40 60 60 125 125 20 30 40 60 120 200 300 400

6 10 14 20 28 40 6 10 14 20 28 40 54 65 80 10 15 20 20 30 30 6 10 14 20 28 40 54 80

2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

7.5 12.5 17.5 25 35 50 7.5 12.5 17.5 25 35 50 67.5 81 100 12.5 19 25 25.0 37.5 37.5 7.5 12.5 17.5 25 35 50 67.5 100

6 10 14 20 28 40 6 10 14 20 28 40 54 65 80 10 15 20 20 30 30 6 10 14 20 28 40 54 80

1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0 1.5 – 3.0

2.95 3.1 3.6 4.2 5.0 5.6 1.9 2.5 2.6 3.4 3.7 4.3 5.5 5.7 7.1 2.15 2.3 2.8 3.3 3.5 3.9 1.3 1.6 1.8 2.65 3.3 4.0 4.9 6.4

Legend * The ***allest permissible pulley diameters were established in standard ambient conditi*** (23 °C, 50 % rel. humidity). Lower temperatures require larger drum diameters. For the P line, this also applies in the case of low humidity. Recommended dmin for power tran***ission: A line: 2.5 x type number E line: 2 x type number P line: 5 x type number (7 x type number at relative humidity < 40 %) ** The nominal effective pull states the possible power tran***ission in N/mm belt width (standard ambient conditi*** 23 °C/50 % rel. humidity) that the belt type can produce at nominal elongation. *** If temperatures are exceeded, please contact Forbo Siegling application engineers.

Supplied as – Roll material for customers to finish themselves – Prepared belts for on-site heating of splices. Please state the type of splice you require, sizes and any pre-tension required. Please contact us about belts lengths 125 m – Special types with perforation or sawn edges (in the P line) on request Explanation of the abbreviati*** used, the type designation and resistances on page 11.

Permissible operating temperatures [°C] (long-term temperature)*** -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+70 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 -20/+80 8

Article number

Total thickness approx. [mm]

dmin [mm]*

Elongation at fitting [% of belt length]

Nominal working elongation [% of belt length]

Selection from product range A, E, P lines

Splice

Ground wedge splice

Z-Splice splice length [mm]

Equipment for finishing the wedge splice (P line)

Equipment for finishing the Z-splice (E line, A line)

110 110 110

35/70 35/70 35/70/110 35/70/110 35/70 70 35/70 70 70 35/70

PG-GM-V/230-T

PP-ZP-V/40-3

● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ●

PG-GM-V/400

PP-ZP-V/80-3

SB-HP-160/150

***X-HC-140/40

Splicing technology All types are made endless with tried-and-tested splicing methods. Using our practical finishing equipment guarantees: – extremely fast preparation and finishing of the splice in the workshop or on the machine

***-HP-120/150 … ***-HP-180/1000-P

– very flexible and durable splices – detailed instructi*** for all tools and equipment and power tran***ission belt types You can obtain our tool overview, tool sheets and instructi*** on request.

***-HC-80/60 … ***-HC-50/40

9

Technical data Permitted operating temperature Td [°C]*** (c***tant temperature) -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 -20/+60 10

Nominal effective pull approx. [N/mm belt width]**

Elongation at fitting [% of belt length]

Nominal working elongation [% of belt length]

Article number

Total thickness approx. [mm]

Aramide cord GT 54A black GT 80A black GG 54A NSTR/NSTR black LT 54A LT 80A Polyester cord UU 10E green UU 14E green UU 20E green GT 10E black GT 14E black GT 20E black GT 28E black GT 40E black GG 10E black GG 14E black GG 20E black GG 28E black GG 40E black LT 10E LT 14E LT 20E LT 28E LT 40E LL 10E LL 14E LL 20E LL 28E LL 40E

810053 810082 811055 810081 810080

1.8 1.9 2.8 2.7 2.8

150 150 150 200 200

dmin [mm]*

54 80 54 54 80

1.0 1.0 1.0 1.0 1.0

0.3 – 1.0 0.3 – 1.0 0.3 – 1.0 0.3 – 1.0 0.3 – 1.0

810011 810012 810013 810028 810027 810026 810029 810032 810033 810035 810031 810036 810030 810001 810002 810003 810004 810005 810006 810007 810008 810009 810010

0.75 0.8 1.2 1.2 1.3 1.9 2.1 2.4 1.8 1.9 2.8 3.1 3.4 2.0 2.1 2.3 2.9 3.2 3.4 3.6 3.8 4.2 4.8

30 30 90 30 50 70 120 160 30 50 70 120 160 40 40 80 130 180 40 60 80 130 180

– – – 10 14 20 28 40 10 14 28 28 40 10 14 20 28 40 10 14 20 28 40

1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5 0.5 – 1.5

Legend * The ***allest pulley diameters permissible were established in normal ambient conditi*** (23 °C, 50 % rel. humidity). Lower temperatures require larger drum diameters.

** The nominal effective pull states the possible power tran***ission in N/mm belt width (standard ambient conditi*** 23 °C/50 % rel. humidity) that the belt type can produce at nominal elongation. *** If temperatures are exceeded, please contact Forbo Siegling application engineers.

Weight approx. [kg/m2] 1.9 2.0 2.8 2.7 2.8 0.7 0.8 1.1 1.2 1.3 1.9 2.2 2.5 1.9 2.0 2.9 3.2 3.5 1.9 2.2 2.5 3.2 3.3 3.4 3.6 3.9 4.2 4.8

Selection from product range Endless line

***ailable lengths and widths [mm] Maximum length [mm]

Minimum length [mm]

Maximum width [mm]

Minimum width [mm]

420 420 420 420 420

13700 13700 13700 13700 13700

10 10 10 10 10

480 480 480 480 480

Type designation for A, E, P line

G G 20 P G G 40 A - 32 UU 30 E - 20 FSTR/FSTR green

Colour我们的合作伙伴:Habasit CODONBELT Optibelt FORBO SIEGLING MEGADYNE GATES mitsuboshi BRECO brecoflex ELATECH

620 620 620 420 420 420 420 420 420 420 420 420 420 420 420 420 420 420 420 420 420 420 420

10100 10100 10100 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700 13700

10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10

320 320 320 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480

Pattern Total thickness [1/10 mm] Tension member material Type no./FU' value** Functional layer/friction layer/top layer Friction coating

Type designation for endless range

GG 10 E L T 10 E GT 80 A

Tension member material Type no./FU' value** Functional layer/friction layer/top layer Friction coating

Abbreviati*** used (all lines) A E G L P T U = = = = = = = Aramide Polyester Elastomer G Chrome-leather Polyamide Mixed or polyamide fabric Urethane

Special properties/resistances (all lines) Siegling Extremultus is antistatic. Truly endless types cannot be lengthened, shortened or repaired. The Siegling Extremultus GT and GG types are not sensitive to oils and greases, as well as commonly-***ailable solvents. However using in oily or greasy conditi*** (e.g. oil vapour) is not to be recommended (risk of the belt slipping – if possible use LT or LL types). The Siegling Extremultus sub-types LL, LT and UU are impervious to machine oils, diesel fuels, petrol, benzene, commercially ***ailable solvents such as ethyl acetate, acetone, etc.; chlorinated hydrocarb*** such as perchloroethylene, etc. Siegling Extremultus is not resistant to organic and inorganic acids. For further details, see the Siegling Extremultus – Technical information brochure (ref. no. 316).

11

Siegling – total belting soluti***

Committed staff, quality-orientated organisation and production processes ensure the c***tantly high standa*** of our products and services. The Forbo Siegling Quality Management System is certified in accordance with DIN EN ISO 9001. In addition to product quality, environmental protection is an important corporate goal. Early on we also introduced an environmental management system, certified in accordance with ISO 14001.

Metrik GmbH Werbeagentur Hannover Technologiemarketing Corporate Design Technical Content

Forbo Siegling Service – anytime, anywhere In the company group, Forbo Siegling employs more than 1800 people worldwide. Our production facilities are located in eight countries; you can find companies and agencies with stock and workshops in more than 50 countries. Forbo Siegling service centres provide qualified assistance at more than 300 locati*** throughout the world.

Ref. no.

上海科动传动系统有限公司

普通会员第18年

|

公司主营:FORBO皮带.SIEGLING皮带.FORBO SIEGLING西格林皮带.SIEGLING输送带...