9A SOLID FILM LUBRICANT

HEAT CURING

SERIES E750

MEETS SAE SPEC AS5272C Type II

FORMERLY MIL-L-46010D TYPE II

TECHNICAL INFORMATION GUIDE

.

Lubricative Pigment Molybdenum Disulfide

Color Flat Dark Gray

Shelf Life 1 year from date of Manufacture

Vacuum Outgassing None @ 10-6 Torr.

Lox Compatibility 100% compatible and shock resistant

Resistivity 1.4 x 106 OHMS CM

Coefficient of Friction 0.0236 (Falex Test)

Load Carrying Capacity 2250 lbs. ASTM D2625 B

Corrosion Protection OVER 1500 hours* ASTM B117

(@ .0005" DFT on DoD-P-16232 Type M

Class 3 phosphated steel)

*Test halted before failure occurred

COMPOSITION AND PHYSICAL PROPERTIES

DESCRIPTION

Sandstrom 9A Dry Film Lubricant is a paint-like coating

containing molybdenum disulfide and corrosion inhibiting

pigments. This Heat Curing material prevents corrosion,

galling, seizing, and fretting. It is a low-friction coating which

exhibits long wear life when operated at -3200F to +5000F

under loads exceeding 100,000 psi.

9A should be applied where maximum wear life and corrosion

protection from a dry film lubricant are required.

Once Sandstrom 9A has been heat cured, it is virtually

unaffected by atmospheric and fretting corrosion, solvents,

acids, oils, degreasers, and is not resoftened again at elevated

temperatures.

9A can be applied to a wide variety of surfaces by spraying

or dipping. Complete application instructi*** are on the

reverse of this sheet.

OUTSTANDING FEATURES/BENEFITS

Excellent Corrosion Protection, Chemical Resistance, and

Long Wear Life are its outstanding characteristics.

SANDSTROM 9A CONTAINS NO GRAPHITE

Use Sandstrom "099" as an alternative to 9A where low VOC

and no lead is preferred. 099's performance is comparable

to 9A.

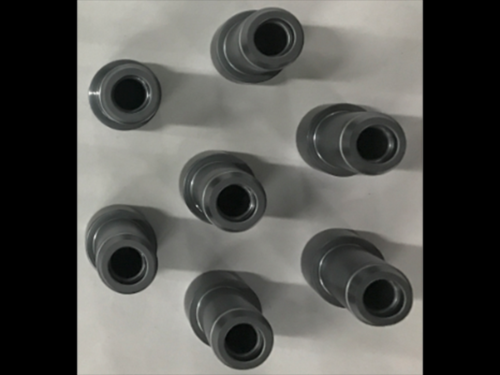

TYPICAL USES

Sandstrom 9A is an excellent solution to the problem of lubricating

parts:

• That will be operated in corrosive atmospheres

• That may be stored for long periods

• Which are seldom lubricated once they le***e the factory and

where permanent lubrication is desired

• Where operating pressures exceed the load-bearing capaci ties

of ordinary oils and greases

• Where "clean operation" is desired (9A will not collect dirt and

debris like grease and oils)

• Where a protective coating and sacrificial break-in lubricant

is needed

• Where fretting and galling is a problem (such as splines,

universal joints, and keyed bearings)

• Where easy release is desired (such as fasteners and PVC

molds)

• Where parts may be subjected to frequent disassembly

Net Wt./ Gallon 9.5 lbs. + .2 lb.

Solids Content 40% minimum (By Wt.)

Viscosity 40 - 46 sec (#1 Zahn cup @ 770F)

Flash Point 440F+ 20F Setaflash

Operating Temp. Range -3200F to +5000F

Vehicle Type Epoxy-Phenolic

VOC 5.5578 lbs./gal. minus water

(Theoretical)

Specificati***: SAE Spec AS5272C

PRI QPL AS5272 type 2

Wear Life: 496 Minutes ***erage

ASTM D2625 A

NOTICE

Before using this product, read all warnings and safety

information printed on the label, the Material Safety Data

Sheet, and the Technical Info-Guide

STIRRING

IMPORTANT! THIS LUBRICANT CONTAINS HE***Y PIGMENTS

WHICH SETTLE RAPIDLY. THEREFORE, IT SHOULD BE

STIRRED THOROUGHLY BEFORE USE AND CONTINUOUSLY

DURING APPLICATION.

THINNING

For spraying* - Use 2 parts 9A to 1 part PM solvent.

For dipping* - Use slow-drying thinner mixture of PM and PMA,

blended 1:1, as to provide proper run-off characteristics. The

suggested starting point is 4 parts 9A to 1 part thinner mixture.

*By volume.

APPLICATION

SANDSTROM 9A should be sprayed or dipped to the desired film

thickness (usually .0003 to .0007 inches). Allow parts to flash off at

least 30 minutes at 770F +50F.

BAKING

BAKING 4000F (2040C) FOR ONE (1) HOUR in a forced draft oven

will yield optimum corrosion protection and wear life.

IMPORTANT! The hour begins when the part has reached 4000F

(2040C), NOT when it is placed in the oven. In cases of very thick

metals, an extra hour may be required to bring the part up to the

proper temperature. Thermocouples may be used to determine

the true temperature of the metal. However, if the metallurgical

properties are adversely affected by baking at this temperature

(i.e., ALUMINUM, in some cases), we would recommend use of

SANDSTROM LC-300 Heat Curing Lubricant which cures at 3000F

(1490C) in ONE (1) HOUR. SANDSTROM 099 could also be used

as it will cure in temperatures ranging from 3000F to 4000F.

IT IS IMPERATIVE TO USE A PROPERLY VENTED OVEN (DIRECT

VENT TO THE OUTSIDE).

CLEANUP

Use the same solvents for cleaning tools as are recommended for

thinning.

REMOVAL OF SANDSTROM 9A

In the event it is necessary to remove Sandstrom 9A, physical

removal is best (such as grit blasting, sanding, or grinding).

**Strict compliance to the instructi*** given in Surface

Treatment, Stirring, and Baking is essential to obtain

optimum results.

WARNINGS: C***tant stirring is imperative for best results.

Caution: Flammable. Keep away from sparks and open flame.

Use with adequate ventilation. ***oid prolonged breathing of

vapors. If swallowed--DO NOT INDUCE VOMITING. Contains

Toluene and Phenolic and Epoxy Resins. Call physician immediately.

GENERAL

Sandstrom 9A is a paint-like material c***isting of lubricative pigments

dispersed in a thermosetting resin system thinned with appropriate solvents.

For maximum service, the APPLICATION INSTRUCTI*** MUST BE

FOLLOWED CLOSELY. The lubricant

is flammable and the safety precauti*** usually followed when using

flammable materials must be observed.

FILM THICKNESS AND ENGINEERING TOLERANCES

As supplied, SANDSTROM 9A will yield a film thickness of about .0005

inches per dip coat. Usually engineering tolerances will permit necessary

minimum film buildup of .0002 to .0003 inches without interference. If excess

buildup does occur and a force fit is necessary, burnishing lightly will assist

in mating the parts. The remaining excess will be worn away in the first few

cycles of operation. Whenever possible, the proper tolerances should be

designed into the part.

COVERAGE

One gallon of this material will cover 660 sq. ft. with a dry film thickness of

.0005 inches. Coverage depends upon methods of application and other

variables such as overspray and type of surface to be coated. Above

coverage rates are based on 100% efficiency.

SURFACE PREPARATION

The following surface preparati*** are recommended for the individual metals

listed in the Application Appendix of the military specification to develop

maximum adhesion, wear life, and corrosion protection. Please contact

Sandstrom Products Company for substitute surface preparati*** if recommended

steps cannot be followed.

Application on steel. Preclean the steel surface with aliphatic naphtha or

any other EPA compliant cleaner that sufficiently cleans surfaces to pass

ASTM F22. Sandblast the surfaces with 180-220 grit aluminum oxide. Phosphate

IAW MIL-DTL-16232 (weight should be 11-22 g/m2), type M, class 3 or

type Z, class 3.

Application on stainless steels. Preclean the steel surface with

aliphatic naphtha or any other EPA compliant cleaner that sufficiently

cleans surfaces to pass ASTM F22. Sandblast the surfaces with 120 grit

aluminum oxide. Passivate the surfaces with ASTM A967, types nitric 1,

nitric 2 or nitric 3, as applicable.

Application on aluminum and aluminum alloys. Preclean the

aluminum surface with aliphatic naphtha or any other EPA compliant

cleaner that sufficiently cleans surfaces to pass ASTM F22. Sulfuric acid

anodize IAW MIL-A-8625 and seal the surface.

Application on titanium and titanium alloys. Degrease the surfaces to

be coated with aliphatic naphtha or any other EPA compliant cleaner that

sufficiently cleans surfaces to pass ASTM F22. Sandblast the surface

with 180-220 grit aluminum oxide and alkaline anodize.

Application on copper and copper alloys. Preclean the copper

surface with aliphatic naphtha or any other EPA compliant cleaner that

sufficiently cleans surfaces to pass ASTM F22. Sandblast the surfaces

with 180-220 grit aluminum oxide. Form a black oxide finish on the

surfaces.

Page 2; Series E750 9A Solid Film Lubricant-Heat Curing

IMPORTANT! ***OID TOUCHING THE SURFACES TO BE

COATED--OIL FROM HANDS WILL INTERFERE WITH

PROPER COATING. Whenever possible treat both contact

surfaces (i.e., the shaft and the bearing).

IMPORTANT NOTICE TO BUYER / WARRANTY AND LIMITATI*** ON OUR LIABILITY

We warrant our products to be free of manufacturing defects, and that they meet our current published physical properties and specificati***. All information and suggesti*** presented are rendered

gratis and is accurate to the best of our knowledge. They are based on technical data which we believe to be reliable, and are intended for use by pers*** h***ing skill and “know-how,” at their own discretion

and risk. Prior to use, customers are cautioned to determine the suitability of our products for any given application through their own testing. NO WARRANTY IS MADE, EXPRESS OR IMPLIED,

REGARDING SUCH INFORMATION, THE DATA ON WHICH IT IS BASED, OR THE RESULTS OBTAINED FROM IT'S USE OR THAT OUR PRODUCT SHALL BE MERCHANTABLE OR FIT FOR ANY

PARTICULAR PURPOSE. SUCH STATEMENTS ARE NOT INTENDED TO SUGGEST INFRINGEMENT OF ANY PATENT. Since conditi*** of use of our products are beyond our control, all suggesti***

and statements are made without guarantee, warranty or other resp***ibility, express or implied, on our part. We assume no resp***ibility for results obtained, or damages incurred, from their use beyond

replacing material proved to be defective or refunding the purchase price of such material at our option. Acceptance of delivery of our product means you h***e accepted the terms of this warranty, whether

or not purchase orders or other documents state terms that vary from this warning. No seller is authorized to make any representati*** or warranty or assume any other liability on our behalf with any sales

of our products. © 2/1/98 SANDSTROM PRODUCTS COMPANY June 24 2009

比尔安达(上海)润滑材料有限公司

普通会员第14年

|

公司主营:ws2涂层,everlube涂层,二硫化钼涂层,MOS2涂层,固体干膜涂层,杜邦(dupont)涂层...

咨询热线:

18221041697