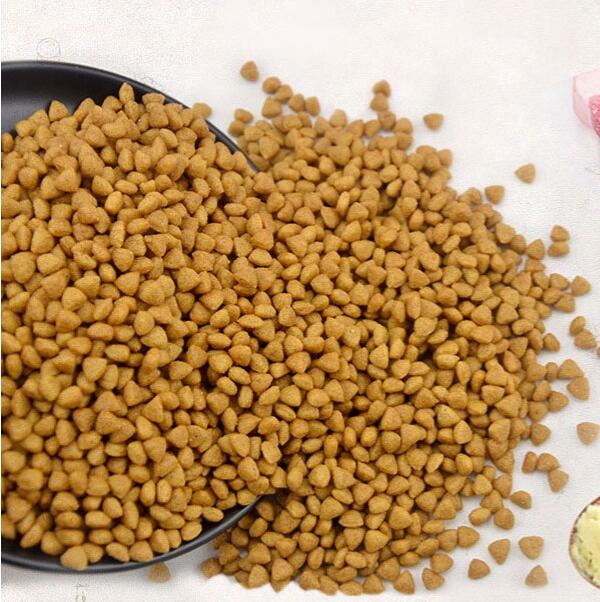

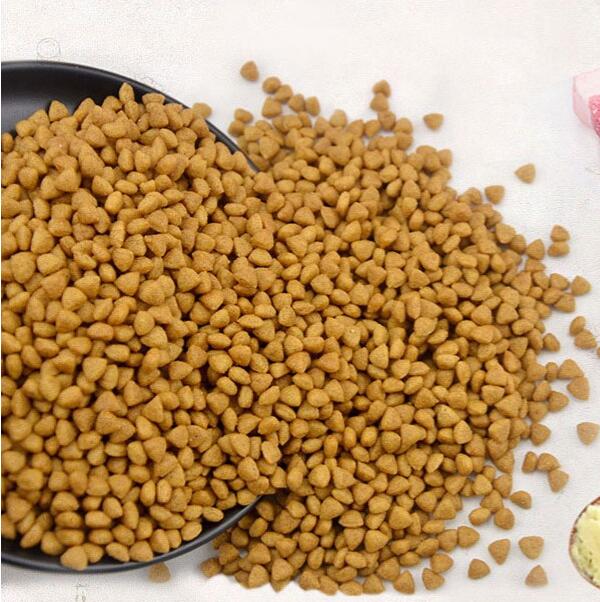

产品简介

该面食机生产线以面粉,淀粉,薯粉等低膨化谷物作为基本原材料,经过挤压膨化熟化成型之后,适度膨化的颗粒毛胚形体规则美观。经过高温油炸的胚体瞬时膨化,淀粉***结构排列次序被打破并短时间内重组,食品颗粒整体均化效果更佳,因此用该生产线加工出的膨化食品,较传统非膨化类休闲食品具有口感酥脆,口味多样,油而不腻的优势。膨化食品设备流程上,该油炸类食品挤压设备生产线无噪音、粉尘等严重污染。部分因油炸产生的有碍环境的轻度污染烟气都通过风机吸收排放的方式排到厂房之外,以保证食品质量安全。膨化食品设备操作上,该油炸类食品挤压设备生产线占地面积小且操作简便,无需多余人工,可大程度降低使用者的人工费用成本。

The flour, starch, potato flour and other low-expansion cereals are used as basic materials in the production line of the flour machine. After extrusion, extrusion and ripening, the shape of the properly expanded granular hair embryo is regular and beautiful. After instantaneous expansion of embryo body, the order of starch structure was broken and reorganized in a short time, and the overall homogenization effect of food particles was better. Therefore, the expanded food processed by this production line has the advantages of crisp taste, diversified taste and oily but not greasy compared with the traditional non-expanded leisure food. In the process of extruding food equipment, the production line of extruding equipment for fried food has no serious pollution such as noise and dust. Some of the slightly polluted fumes which are harmful to the environment caused by frying are discharged out of the factory buildings by the way of absorption and discharge of fans to ensure the quality and safety of food. In the operation of extruded food equipment, the production line of fried food extrusion equipment covers a ***all area and is easy to operate. It does not need extra labor, and can greatly reduce the labor cost of users.

品质保证

1、拌粉机:根据生产线产量的不同可选用不同型号的拌粉机。

2、上料机:利用电机为动力螺旋式输送,确保上料方便快捷,省时省力,安全卫生,。

3、膨化机:根据生产线产量的不同选用不同型号的MT型膨化主机。

4、切断机:面食切断机,具体形状、大小、长短可根据客户要求调节推荐不同切断机。

5、油***:分为电油***和燃油(气)油***,可根据客户要求配置,甩油机更节省人力,杜绝浪费。

6、调味线:有八角筒、圆筒、提升单滚筒、双滚筒调味线,根据产量、产品性质配置,

1. Flour mixer: Different types of flour mixer can be selected according to the output of the production line.

2. Feeder: Use motor as power screw conveyor to ensure that feeding is convenient, time-s***ing, labor-s***ing, safe and sanitary.

3. Extruder: According to the different output of production line, different types of MT extruder are selected.

4. Cutter: pasta cutter, the specific shape, size, length can be adjusted according to customer requirements recommend different cutters.

5. frying pan: divided into electric frying pan and fuel (gas) frying pan, can be configured according to customer requirements, oil throwing machine s***es more manpower and eliminates waste.

6. Seasoning line: octagonal drum, cylinder, lifting single drum, double drum seasoning line, according to the output, product nature configuration.

***服务

1.提供各类基础配方;

2.多种形状可供选择;

3.免费安装调试;

4.负责培训人员;

5.免费保修一年。

6.生产线长度大约15米左右,可以根据客户的厂房尺寸拐弯摆放。

7.客户可提供厂房尺寸,工程师免费设计配置机器。