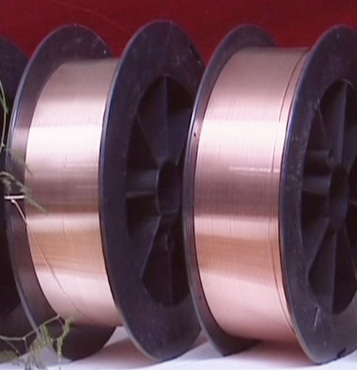

上海斯米克HS214铝青铜焊丝

名称:S214铝青铜焊丝

标准:GB/T9460 SCu6100A AWS A5.7ERCuAl-Al

成分:Al=7.0-8.5%;Fe≤0.5%;Cu余量。

说明:S214是一种无铁的铝青铜焊丝,熔点为1030-1040℃,能抗轻载荷的磨损,耐海水以及常用酸类的腐蚀。

用途:适用于镀铝钢板,船用螺旋桨、滑轨、滑面和承载面的堆焊以及机械制造业、化学工业和造船工业中灰口铸铁的连接焊和堆焊,抗腐蚀的铝青铜或黄铜的焊接。

许可证号:XK06-009-0124

|

Copper alloys

铜

合

金 |

S 201 |

Sn1 Si0.3Mn0.3 |

Good mechanical properties and crack resistance. Gas welding and argon arc welding of red copper. |

ERCu |

|

S 211 |

Si3 Mn1 |

Good mechanical properties. Argon arc welding of copper alloys and MIG brazing of steel. |

ERCuSi-Al |

|

|

S 212 |

Sn5 Cu Rem. |

Wear resistance. Argon arc welding of copper alloys and surfacing of steel. |

ERCuSn-A |

|

|

S 213 |

Sn8 Cu Rem. |

Wear resistance. Argon arc welding of copper alloys and surfacing of steel. |

ERCuSn-C |

|

|

S 214 |

Al7.5 Cu Rem. |

Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. |

ERCuAl-A1 |

|

|

S 215 |

Al9 Cu Rem. |

Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. |

ERCuAl-A2 |

|

|

S 221 |

Cu60 Sn1 Si0.3 |

Melting point is about 890℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. |

|

|

|

S 221F |

Cu60 Sn1 Si 0.3 |

S221 welding rod coated with flux. |

|

|

|

S 222 |

Cu58Sn0.9Si0.1 |

Melting point is about 880℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. |

RBCuZn-C |

|

|

S 222F |

Cu58Sn0.9Si0.1 |

S222 welding rod coated with flux. |

RBCuZn-C |

|

|

S 223 |

Cu59 Sn0.6 |

Melting point is about 900℃. Braze welding of copper, steel and cast iron. |

RBCuZn-A |

|

|

S 224 |

Cu62 Si0.5 |

Melting point is about 905℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. |

|

说明:S214是一种钨铁的铝青铜焊丝,能抗轻载荷的磨损,耐海水、微咸水以常用酸类的腐蚀。

用途:适用于镀铝干板的***弧钎焊,船用螺旋桨、滑轨、滑面和承载面的堆焊以及机械制造业、化学工业和造船业中灰口铸铁的连接焊和堆焊,抗腐蚀的铝青铜或特殊黄铜管道的***弧焊。

焊丝化学成分(%)

|

AI |

Fe |

Cu |

|

7.0-8.5 |

≤0.5 |

余量 |

物理特性(相似值)

|

比重 Kg/dm |

熔化温度 ℃ |

热导率 w/m..k |

线膨胀系数 10-6/k(20-300℃) |

导电率 %IACS |

|

7.7 |

1030-1040 |

65 |

17.0 |

12-15 |

融敷金属机械性能(参数值)

|

抗拉强度 MPa |

延伸率 % |

布摄硬度 HB |

冲击韧性 J |

|

430 |

40 |

100 |

100 |

注意事项:

1. ***弧焊时建议用大流量、底流速的气流,以保证焊接熔池得到良好的保护。

2. 薄板爱用I型坡口;较厚的板采用V型或X型坡口,需加衬垫。

3. 不推荐把这种焊丝用于气焊,因为在焊接熔池中会有铝的氧化物存在,影响焊缝质量