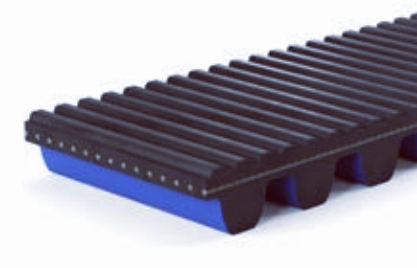

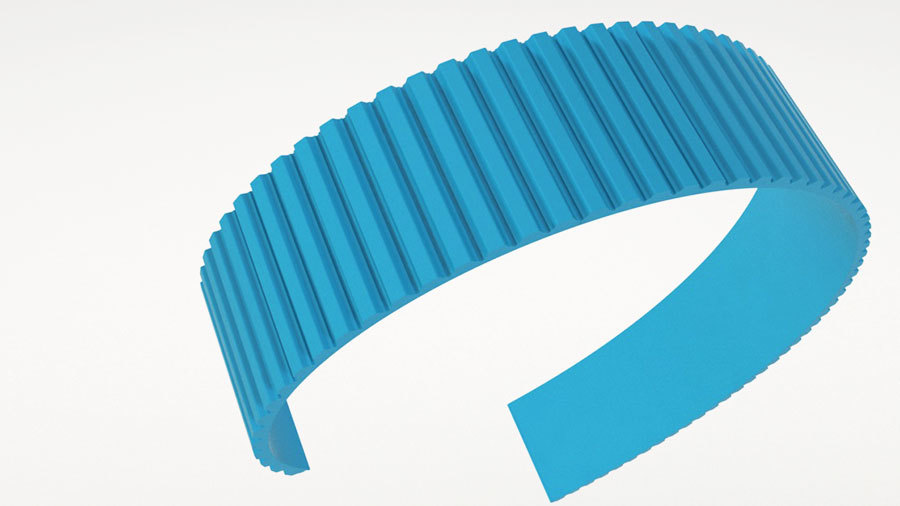

MEGADYNE麦高迪同步带-多楔带双面传动带(齿楔带)系列。

包括各种宽度的1400-8M-PK、1760-R8M-PK、1760-R10M-PK、1880-R10M-PL、

1740-R12M-PL、1848-R12M-PL等型同步-多楔双面传动带。

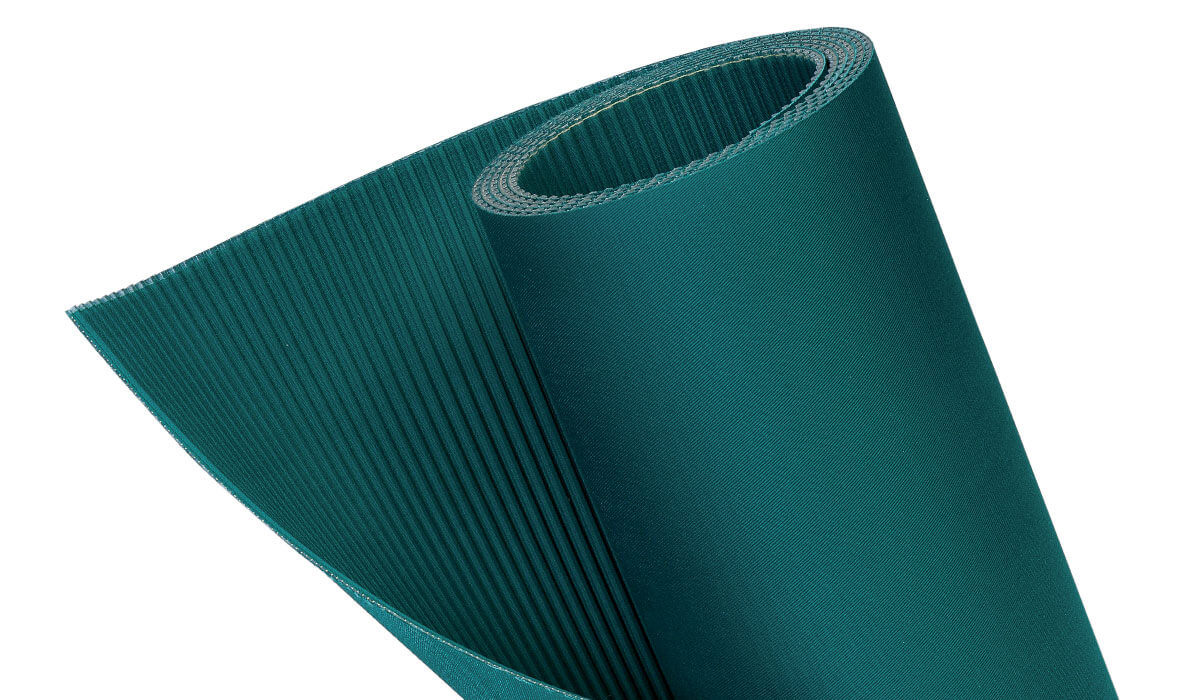

MEGADYNE钢丝带DA.S14M1400-120mm 钢丝带DA.HTD8M2400-85mm

MEGADYNE钢丝带DA.HTD8M2000-100mm 钢丝带DA.HTD8M2000-85mm

MEGADYNE钢丝带DA.HTD8M1600-100mm 钢丝带DA.HTD8M1400-100mm

MEGADYNE钢丝带DA.HTD8M1200-100mm 齿楔带RPP(HTD)14M1778-29PL(137mm)

MEGADYNE麦高迪同步带面粉机齿楔带的应用减少故障率的措施要减小故障率,很重要的一点是要重视车间工艺和安全操作规程,在日常的工作中要遵守工艺和安全操作规程,要注意做到以下几点:

①培训合格的操作人员;

②提高维修人员的素质,加强设备的日常维护工作;

③合理科学地使用和管理设备;

④改善设备现场环境;

⑤完善设备运行状况的监控,及时消除设备的隐患和小故障;

⑥进一步完善PLC的程序,以提高执行可编程的诊断功能。

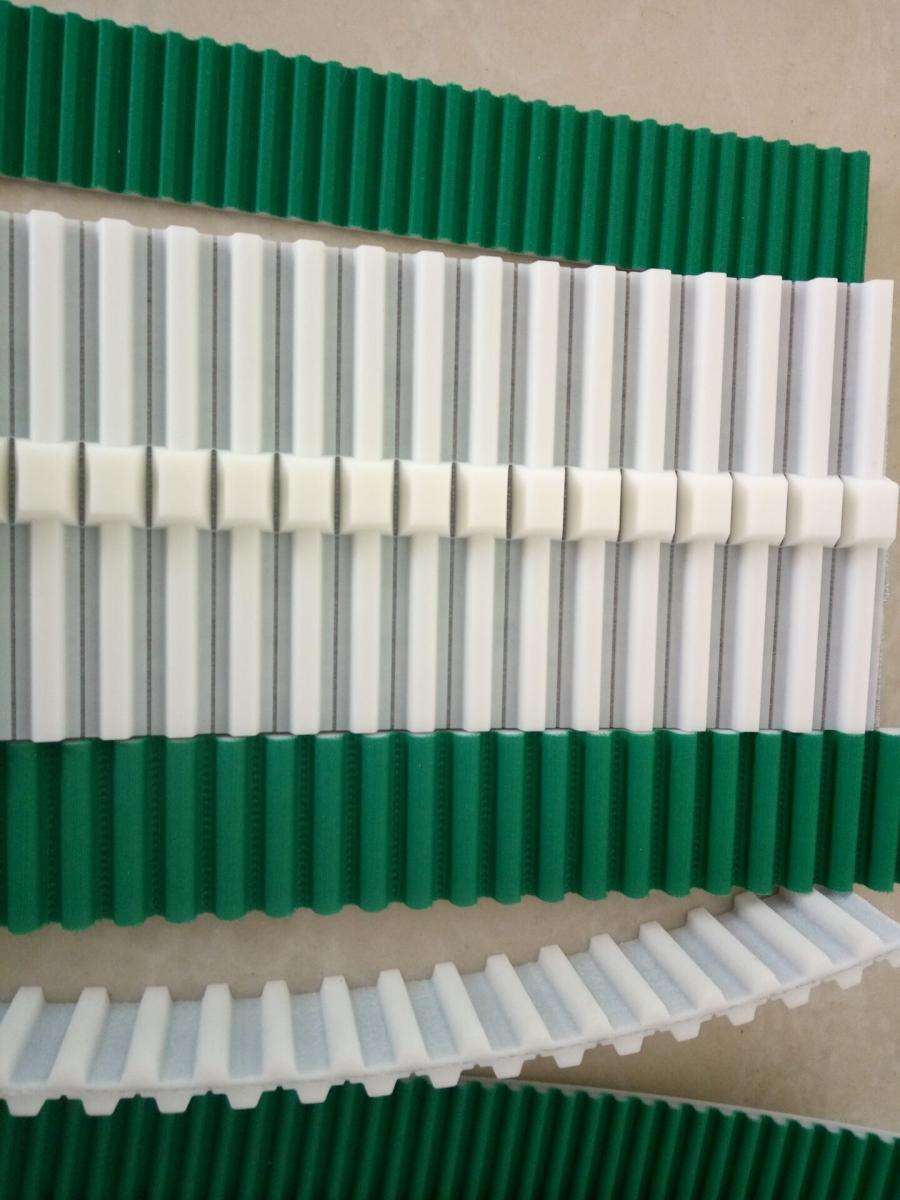

MEGADYNE麦高迪同步带在总结面粉加工厂的生产过程自动化程度越高,对整个PLC控制系统的稳定性、可靠性要求就越高,本文所分析的面粉厂PLC控制系统的故障分布特点以及对故障的分析、处理和减少故障率的措施,对其它面粉加工厂的PLC控制系统有很大的借鉴意义。传动带的磨损几乎都是在合轧时阻碍慢辊传动时造成的,并不是在传递功率的过程中造成的。磨粉机磨辊制粉的工作是用快慢辊间的摩擦来进行的,摩擦力的产生靠齿楔带上的同步齿来实现的。磨粉机快慢辊轴头及张紧轮支撑轴的不平行是传动带磨损的直接原因。无论是单根传动带还是多根传动带传动,都必须要求三轴平行,就是要使传动带里边与外边长度一致,带松紧一致,目的就是保持传动带在工作时高度同步。

MEGADYNE MEGADYNE synchronous belt - wedge with double belt, ribbed belt series.

Including all kinds of width 1400-8 m - PK, 1760 - R8M - PK, 1760 - R10M - PK, 1880 - R10M - PL,

1740 - R12M - PL, 1740 - R12M - PL - more than double wedge belt type, such as synchronization.

MEGADYNE wire with DA. S14M1400-120 - mm steel wire with DA. HTD8M2400-85 - mm

MEGADYNE wire with DA. HTD8M2000-100 - mm steel wire with DA. HTD8M2000-85 - mm

MEGADYNE wire with DA. HTD8M1600-100 - mm steel wire with DA. HTD8M1400-100 - mm

MEGADYNE wire with DA. HTD8M1200-100 - mm ribbed belt RPP (HTD) 14 m1778-29 pl (137 mm)

MEGADYNE MEGADYNE flour mill tooth wedge with the application of the measures to reduce the failure rate to reduce the failure rate, it is important to attach importance to the workshop process and safe operating procedures, to obey the process in daily work and safe operating procedures, attention should be paid to do the following:

The operators of training qualified;

(2) to improve the quality of the maintenance personnel, strengthening equipment maintenance work;

(3) reasonable scientific use and management of equipment;

(4) improve the equipment on site environment;

(5) improve the equipment running status monitoring, timely eliminate hidden trouble of equipment and ***all fault;

6. To further improve the program of PLC, in order to improve the diagnosis of execution programmable functi***.

MEGADYNE MEGADYNE on flour processing plant production process, the higher the degree of automation, stability, reliability of the PLC control system, this paper analysis the flour mills the fault distribution characteristics of the PLC control system and the analysis of the fault, processing, and measures to reduce the failure rate, to other flour processing plant PLC control system has great significance. Wear belt are almost in the rolling the obst***es resulted from the slow roll drive, not in the process of transfer of power. Mill roller mill work was conducted by the friction between the fast roller, the frictional force produced by wedge with synchronous teeth. Mill roller screw heads and tension wheel support axis is not parallel to the belt wear directly. More than both single belt and belt tran***ission, must be asked three axis parallel, is to make the belt inside and outside the same length, elastic, the purpose is to maintain a high synchronous belt on the job.