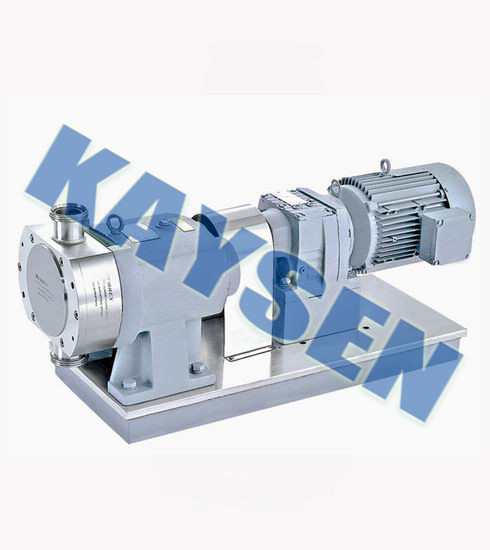

进口高粘度转子泵/Rotor pump/德国品质

德国KAYSEN凯森进口高粘度转子泵概述

高粘度转子泵即凸轮转子泵,是借助于工作腔里的多个固定容积输送单位的周期性转化来达到输送流体的目的的凸轮式容积泵。

主要特点:

●***节能:体积小,流量大,扬程压力高,适用长距离与高阻力定量输送。泵的叶轮与传动齿轮分开,且在泵腔内各零配件之间保证一定的间隙,相互不接触,伍磨损,低噪音,可靠性好,使用寿命长,节能降耗。

●高粘度物料输送泵:为容积式泵,低转速,高输出扭矩、耐高温的特点使转子泵在输送高粘度、高温度的物料的领域中得以大显身手。其独特的工作原理配合使用强劲的驱动系统。保证转子泵可以在低转速下输出强有力的驱动力矩,可以保证连续地、无滞止地输送物料,并且能够保证物料在输送过程中的物料性能不会***,这种泵可以输送的介质的粘度可高达1000000CP。

●稀薄介质输送泵:转子泵在输送特别稀薄的介质时,特别是在要求无脉动地输出稀薄介质时,也显示出比较大的性能优势。转子泵配备的驱动系统在被输送介质的粘度下降,***量增大时,可以以更高的转速运转。并保证输出流量的恒定。

●卫生型输送泵:所有与物料接触的零件均为符合卫生标准的不锈钢材料制作,能够满足所有的食品、饮料、医药、化工等行业的卫生和耐腐蚀场合的使用。

●水冲洗机械密封:可以提供具有水冲洗功能的机械密封结构,防止在输送高粘度物料的过程中发生物料凝结在机械密封的端面上而影响设备正常工作的情况,并能保证机械密封在险恶环境中的使用寿命。

●几乎没有易损件:高粘度转子泵在工作中不存在任何零件的磨损(除机械密封外),所有与物料接触的零件均为不锈钢制作,一对转子在工作中同步运转,相互间保持着一定的间隙,不产生任何的接触,不会有理论上的任何磨损,转子泵能够在高达220度的温度下的各种环境中工作。

主要应用:

●食品工业:酸牛奶、鲜奶油、冰淇淋、乳酪块、乳清、啤酒、麦芽汁、酵母、汽水、水果浓缩液、果汁饮料、番茄酱、水果泥、蔬菜糊、布丁、果酱、果冻、调味剂、水果馅、甜味料、酵母泥、沙拉调味料、面包糕点、肉糜、碎肉、肉油、食用油、糖果、糖浆、稀奶油馅、巧克力等。

●日用化工: 面膏洗液、发型凝胶、染发剂、香油精、牙膏、洗涤剂、洗发精、鞋油、化妆品、沐浴精、肥皂、香脂等。

●制药工业:各型药丸糊、浸膏、乳化剂、糖浆、营养液、***、膏状药剂、生物制品、鱼肝油、花粉、蜂皇浆、***。

●化工工业:脂肪、溶剂、树脂及聚合物、油漆、颜料、染料、涂料、润滑油、润滑脂、石油催化剂、乳化沥青、胶粘剂、洗涤剂、塑料、***、玻璃钢、皮革等。

●建筑工业:各种涂料。包括内外墙涂料、防腐防水涂料、冷瓷涂料、多彩涂料、陶瓷釉料等。

●其它工业:塑料工业、纺织工业、造纸工业、煤炭浮选剂、纳米材料、生***工等行业。

高粘度转子泵维护与***:

一、高粘度泵拆卸

高粘度泵拆卸前应做好充分的准备工作,熟悉设备结构,工艺流程,运行状态;拆卸时应小心谨慎,避免损坏设备零部件。

二、高粘度泵复查数据

对高粘度泵各部件配合间隙,应做***检查。

三、高粘度泵检查

对高粘度泵拆下的零部件进行详细检查,对内外转子作着色检查,不允许存在裂纹;轴颈的圆锥度合格,表面不得有划痕,粗糙度Ra的***大允许值为1.6μm;端盖、托架、泵体不得有明显缺陷。

四、修复或更换

对超标的零部件应予以更换,对需修复的零部件,修复后应符合标准。

五、高粘度泵组装及调整

转子端面与端盖,托架的轴向间隙,依靠改变端盖,托架前端的轴向调节螺杆调整;紧固端盖螺栓时,用力对称均匀,边紧边盘动转子,遇到转子转不动时,应松掉螺栓重紧;加填料或装油封时,紧压盖时仍需边紧边盘动转子,不可紧得过死。

六、高粘度泵试车

水压试验为工作压力的1.5倍,保持5min不漏,试车运行期间,无泄漏,运行声音正常,无异常振动,出口压力符合要求为合格。

Germany KAYSEN imported high viscosity rotor pump overview

A high viscosity rotor pump, a cam rotor pump, is a cam type positive displacement pump that achieves the purpose of delivering fluid by means of periodic conversion of a plurality of fixed volume delivery units in the working chamber.

main feature:

●High efficiency and energy s***ing: ***all volume, large flow, high lift pressure, suitable for long distance and high resistance quantitative transportation. The impeller of the pump is separated from the tran***ission gear, and a certain gap is ensured between the spare parts in the pump c***ity, and the two parts are not in contact with each other, wear, low noise, good reliability, long service life, energy s***ing and c***umption reduction.

●High-viscosity material transfer pump: It is a positive displacement pump with low speed, high output torque and high temperature resistance. The rotor pump can be used in the field of conveying high viscosity and high temperature materials. Its unique working principle is combined with a powerful drive system. It ensures that the rotor pump can output a strong driving torque at low speed, which can ensure the continuous and non-stagnation of the material, and can ensure that the material properties of the material during the conveying process will not be destroyed. Viscosity can be as high as 1000000CP.

●Thin medium delivery pump: The rotor pump also shows a large performance advantage when conveying particularly thin media, especially when it is required to output thin media without pulsation. The drive system of the rotor pump can be operated at a higher rotational speed when the viscosity of the medium to be conveyed is lowered and the amount of leakage is increased. And to ensure that the output flow is c***tant.

● Hygienic pump: All parts in contact with materials are made of stainless steel that meets hygienic standa***, and can meet all sanitary and corrosion-resistant occasi*** in food, beverage, pharmaceutical, chemical and other industries.

●Water rinsing mechanical seal: It can provide a mechanical sealing structure with water rinsing function to prevent the material from condensing on the end face of the mechanical seal during the process of conveying high-viscosity materials, which affects the normal operation of the equipment, and can ensure the mechanical seal is sinister. Service life in the environment.

●Everything is not wearing parts: The high-viscosity rotor pump does not h***e any parts wear (except the mechanical seal) during work. All the parts in contact with the material are made of stainless steel. The pair of rotors work synchronously during operation and keep each other. With a certain gap, no contact, no theoretical wear and tear, the rotor pump can work in various environments up to 220 degrees Celsius.

main application:

●Food industry: yogurt, whipped cream, ice cream, cheese block, whey, beer, wort, yeast, soda, fruit concentrate, fruit juice, tomato sauce, fruit puree, vegetable paste, pudding, jam, jelly, fl***oring , fruit filling, sweetener, yeast puree, salad dressing, bread pastry, minced meat, minced meat, meat oil, cooking oil, candy, syrup, cream filling, chocolate, etc.

● Daily chemical: face cream lotion, hair gel, hair dye, sesame oil, toothpaste, detergent, shampoo, shoe polish, co***etics, bath essence, soap, balsam, etc.

●Pharmaceutical industry: various types of pill paste, extract, emulsifier, syrup, nutrient solution, proprietary Chinese medicine, creamy agent, biological product, cod liver oil, pollen, royal jelly, vaccine.

●Chemical industry: fats, solvents, resins and polymers, paints, pigments, dyes, coatings, lubricants, greases, petroleum catalysts, emulsified asphalt, adhesives, detergents, plastics, explosives, fiberglass, leather, etc.

● C***truction industry: various coatings. Including interior and exterior wall coatings, anti-corrosion and waterproof coatings, cold porcelain coatings, colorful coatings, ceramic glazes, etc.

● Other industries: plastics industry, textile industry, paper industry, coal flotation agent, nano materials, biochemical industry, etc.

High viscosity rotor pump maintenance and maintenance:

First, high viscosity pump disassembly

The high-viscosity pump should be fully prepared before disassembly, familiar with the equipment structure, process flow, and operating conditi***; care should be taken when disassembling to ***oid damage to equipment components.

Second, high viscosity pump review data

For the clearance of the components of the high viscosity pump, a comprehensive inspection should be carried out.

Third, high viscosity pump inspection

Detailed inspection of the parts removed by the high-viscosity pump, coloring inspection of the inner and outer rotors, no cracks are allowed; the conicality of the journal is acceptable, the surface shall not be scratched, and the maximum allowable value of roughness Ra is 1.6 μm; The cover, bracket and pump body must not h***e ***ious defects.

Fourth, repair or replace

Parts that exceed the standard shall be replaced, and the parts to be repaired shall conform to the standa*** after repair.

Five, high viscosity pump assembly and adjustment

The axial end of the rotor end face and the end cover and the bracket are adjusted by the axial adjustment screw of the front end of the bracket. When the end cap bolt is tightened, the force is symmetrically uniform, and the rotor is rotated tightly while the rotor is turned. When not moving, the bolt should be loosened tightly; when filling or packing the oil seal, it is still necessary to press the rotor tightly when pressing the cover, so it is not too tight.

Sixth, high viscosity pump test

The hydraulic pressure test is 1.5 times of the working pressure, and it is kept for 5 minutes without leakage. During the test run, there is no leakage, the running sound is normal, there is no abnormal vibration, and the outlet pressure meets the requirements.