进口高粘度泵/High viscosity pump/德国品质

德国KAYSEN凯森进口高粘度泵概述

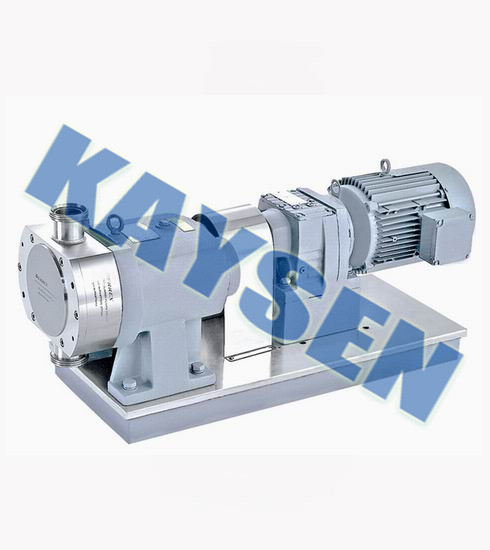

高粘度不锈钢泵是一种容积式内转子泵,也叫 不锈钢高粘度泵。高粘度不锈钢泵的自吸性能强,适用于输送不含固体颗粒和纤维的粘稠液体,甚至是半固体状态的液体,高粘度不锈钢泵 ***高输送粘度达到300000cst厘泊。高粘度不锈钢泵 具有体积小、重量轻、脉动小、噪音低、运转平稳、寿命长等优点。高粘度不锈钢泵 采用外部润滑方式。轴承部分和泵腔工作部分由密封部分隔开,轴承部分可通过油杯从外部定期加油润滑。泵体内设有加热或冷却夹套,可通过外部装置实现加温或降温过程。 高粘度不锈钢泵 可配安全阀,当泵或管路系统超压时,安全阀打开,形成内部回流,保证系统安全。泵有泵体、泵盖、安全阀部分、主动轴、内、外转子、支座、轴承等部分组成。泵装置由泵、电机和底座组成。泵和电机固定安装在底座上,传动方式有皮带传动和联轴器直联两种方式。

主要特点:

●设计简单、结构紧凑,便于安装和维护。

●输送液体平稳,无脉动,振动小,噪音低。

●有很强的自吸性能。

●正确选用零件材料,可输送多种有腐蚀性的介质,适用温度可达300℃。

●内外转子转向相同,磨损小,使用寿命长。

●输送液体的种类和粘度范围广。

●泵的转速与流量呈线性函数关系,可适当改变转速来改变泵的流量。

●端面间隙易于调节,当转子磨损后不用拆泵即可方便地调整端面间隙来适应工况要求。

主要应用:

石油、化工、沥青、涂料、油脂、医药、染料、食品等行业。

高粘度泵维修与***

一、高粘度泵拆卸

高粘度泵拆卸前应做好充分的准备工作,熟悉设备结构,工艺流程,运行状态;拆卸时应小心谨慎,避免损坏设备零部件。

二、高粘度泵复查数据

对高粘度泵各部件配合间隙,应做***检查。

三、高粘度泵检查

对高粘度泵拆下的零部件进行详细检查,对内外转子作着色检查,不允许存在裂纹;轴颈的圆锥度合格,表面不得有划痕,粗糙度Ra的***大允许值为1.6μm;端盖、托架、泵体不得有明显缺陷。

四、修复或更换

对超标的零部件应予以更换,对需修复的零部件,修复后应符合标准。

五、高粘度泵组装及调整

转子端面与端盖,托架的轴向间隙,依靠改变端盖,托架前端的轴向调节螺杆调整;紧固端盖螺栓时,用力对称均匀,边紧边盘动转子,遇到转子转不动时,应松掉螺栓重紧;加填料或装油封时,紧压盖时仍需边紧边盘动转子,不可紧得过死。

六、高粘度泵试车

水压试验为工作压力的1.5倍,保持5min不漏,试车运行期间,无泄漏,运行声音正常,无异常振动,出口压力符合要求为合格。

高粘度正确使用方法

高粘度泵具有输送液体平稳、无脉动、震动小、噪音低、自吸性能强等多种优点,但客户在使用高粘度泵的时候仍然需要注意一些事项。

1、现场进出口管路管径尽量和泵的口径一致,当输送的介质粘稠度很高的情况时,现场管路的进口口径***好大于泵的进口口径,这样能减少进口阻力。

2、现场管路应尽量减少弯头的数量,且弯头角度不易过小,进口管线不易过长。

3、启动泵组前每个注油杯都应加润滑油,要每隔几天观察加油。

4、泵在工作前,进出口管道阀门全部打开,应点动启机,观察转向和规定转向是否一致。

5、开机后观察运转是否正常,如有不正常噪音、特殊振动时,要停机检查,检查基座是否平稳,联轴器是否同轴。

6、高粘度泵连接方式有减速电机直连和皮带连接,减速机连接的要注意保持干燥不能潮湿或进水,皮带连接的要注意皮带松紧是否恰当,每半年调整一次。

7、泵长期不使用时,应将泵腔内介质排出,并将泵腔清洗干净。

Germany KAYSEN imported high viscosity pump overview

The high viscosity stainless steel pump is a positive displacement internal rotor pump, also known as stainless steel high viscosity pump. The high-viscosity stainless steel pump is self-priming and is suitable for conveying viscous liquids containing no solid particles and fibers, even liquids in semi-solid state. High-viscosity stainless steel pumps h***e a maximum transport viscosity of 300,000 cst centipoise. The high-viscosity stainless steel pump has the advantages of ***all size, light weight, ***all pulsation, low noise, stable operation and long service life. The high viscosity stainless steel pump is externally lubricated. The bearing portion and the working portion of the pump chamber are separated by a sealing portion, and the bearing portion can be periodically lubricated from the outside through the oil cup. The pump body is provided with a heating or cooling jacket, which can be heated or cooled by an external device. The high viscosity stainless steel pump can be equipped with a safety valve. When the pump or piping system is overpressured, the safety valve opens to form an internal recirculation to ensure system safety. The pump has a pump body, a pump cover, a safety valve part, a drive shaft, inner and outer rotors, bearings, bearings and the like. The pump unit c***ists of a pump, a motor and a base. The pump and motor are fixedly mounted on the base. The tran***ission mode includes belt drive and coupling direct connection.

main feature:

●Simple design and compact structure for easy installation and maintenance.

●The conveying liquid is stable, no pulsation, low vibration and low noise.

● Has a strong self-priming performance.

●The correct selection of parts and materials can transport a variety of corrosive media, suitable for temperatures up to 300 °C.

●The inner and outer rotors h***e the same steering, low wear and long service life.

● A wide range of types and viscosities of liquids to be transported.

● The speed of the pump is linearly related to the flow rate. The speed can be changed to change the flow of the pump.

●The end face clearance is easy to adjust. When the rotor is worn, the end face clearance can be easily adjusted to meet the working conditi*** without disassembling the pump.

main application:

Petroleum, chemical, asphalt, coatings, grease, pharmaceuticals, dyes, food and other industries.

High viscosity pump repair and maintenance

First, high viscosity pump disassembly

The high-viscosity pump should be fully prepared before disassembly, familiar with the equipment structure, process flow, and operating conditi***; care should be taken when disassembling to ***oid damage to equipment components.

Second, high viscosity pump review data

For the clearance of the components of the high viscosity pump, a comprehensive inspection should be carried out.

Third, high viscosity pump inspection

Detailed inspection of the parts removed by the high-viscosity pump, coloring inspection of the inner and outer rotors, no cracks are allowed; the conicality of the journal is acceptable, the surface shall not be scratched, and the maximum allowable value of roughness Ra is 1.6 μm; The cover, bracket and pump body must not h***e ***ious defects.

Fourth, repair or replace

Parts that exceed the standard shall be replaced, and the parts to be repaired shall conform to the standa*** after repair.

Five, high viscosity pump assembly and adjustment

The axial end of the rotor end face and the end cover and the bracket are adjusted by the axial adjustment screw of the front end of the bracket. When the end cap bolt is tightened, the force is symmetrically uniform, and the rotor is rotated tightly while the rotor is turned. When not moving, the bolt should be loosened tightly; when filling or packing the oil seal, it is still necessary to press the rotor tightly when pressing the cover, so it is not too tight.

Sixth, high viscosity pump test

The hydraulic pressure test is 1.5 times of the working pressure, and it is kept for 5 minutes without leakage. During the test run, there is no leakage, the running sound is normal, there is no abnormal vibration, and the outlet pressure meets the requirements.

High viscosity correct use method

The high-viscosity pump has the advantages of ***ooth liquid delivery, no pulsation, low vibration, low noise, and strong self-priming performance. However, customers still need to pay attention to some matters when using high-viscosity pumps.

1. The diameter of the on-site inlet and outlet pipelines should be the same as the diameter of the pump. When the medium to be conveyed is highly viscous, the inlet diameter of the pipeline is preferably larger than the inlet diameter of the pump, which can reduce the inlet resistance.

2. The pipeline on the site should minimize the number of elbows, and the angle of the elbow is not too ***all, and the inlet pipeline is not too long.

3. Each oil-filling cup should be lubricated before starting the pump set. Observe the oil every few days.

4. Before the pump is in operation, the inlet and outlet pipeline valves are all open, and the machine should be started to observe whether the steering and the specified steering are c***istent.

5. Observe whether the operation is normal after starting up. If there is abnormal noise or special vibration, stop the inspection, check whether the base is stable, and whether the coupling is coaxial.

6. The high-viscosity pump connection mode includes direct connection of the geared motor and belt connection. The connection of the reducer should be kept dry and not wet or water. The belt connection should pay attention to whether the belt is tight or not, and adjust it once every six months.

7. When the pump is not used for a long time, the medium in the pump chamber should be drained and the pump chamber cleaned.