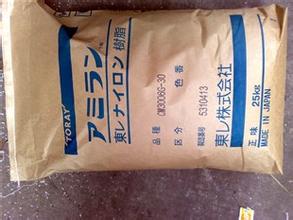

PA6 CM1011G-30---Cm1011g-30 is a polyamide 6 (nylon 6) product with 30% glass fiber reinforcement as filler. It is available in North America, Europe or Asia Pacific. Typical application areas: automotive industry. Main characteristics: flame retardant / rated flame.

Impact performance - unit system test method after drying and adjustment

Notched impact strength of simply supported beams ISO 179

-40°C 10 17 kJ/m² ISO 179

23°C 15 23 kJ/m² ISO 179

Notchless impact strength of simply supported beams ISO 179

-40°C 70 80 kJ/m² ISO 179

23°C 80 100 kJ/m² ISO 179

Unit system test methods for thermal performance, drying and conditioning

Hot deformation temperature (0.45 MPa, UN annealed) 224 - - C ISO 75-2 / b

Melting temperature: 225 - - C DSC

Linear coefficient of thermal expansion - flow 2.0e-5 to 3.0e-5 -- cm / cm / ° C ISO 11359-2

Specific heat: 1600 -- J / kg / ℃

The thermal conductivity is 0.38 -- w / M / K

Unit system test method for electrical performance after drying and adjustment

Volume resistivity: 1.0e + 15.1.0e + 12 ohms · cm IEC 60093

Dielectric strength: 20.18 kV / mm IEC 60243-1

Dielectric constant 4 IEC 60250

23°C, 50 Hz 4.90 10.7 IEC 60250

23°C, 1 kHz 4.60 7.90 IEC 60250

23°C, 1 MHz 4.00 4.30 IEC 60250

Dissipation factor 5 IEC 60250

23°C, 50 Hz 0.030 0.17 IEC 60250

23°C, 1 kHz 0.030 0.18 IEC 60250

23°C, 1 MHz 0.030 0.070 IEC 60250

Arc resistance 6 131 137 sec UL 746