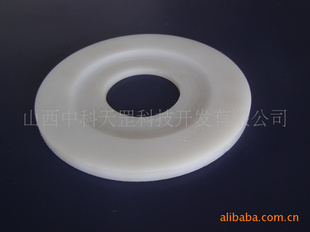

| 材质 | uhmwpe | 用途 | 一级耐磨 |

| 每件重量 | 0.6(Kg) | 外观 | 圆片 |

| 产商 | 山西天罡 |

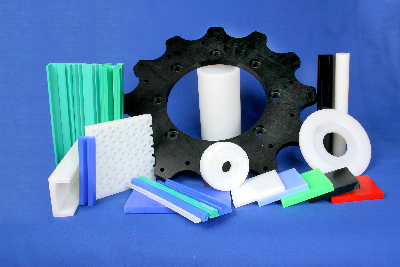

Ultra-high molecular weight polyethylene( UHMWPE for short) is a kind of polyethylene whose volume of molecular beyond 150 million. Molecular formula: —(—CH2-CH2—)—n— Density:0.936~0.964g/cm3 Heat-transformation temperature(0.46MPa)85℃ Melting limit: 130~136℃。 The feature of UHMWPE are:supreme wear-resistance, excellent low-temperature impact-resistance, self-lubrication, innocuity, water-resistance, chemical-resistance, and heat-resistance. Its nature is much better than usual PE as PE is normally lower heat-resistant, worse process forming, harder appearance, stiffer, worse slow-change-resistant compare with usual industrial plastic and larger swelling index. Since it performs bad in fluidity and has much higher viscidity when melting, UHMWPE is a kind of rubber-like high-sticky and teasing substance which could only be produced by pressing and agglomerating in the early age but now is able to be formed through extruding, injection and blowing.. Special performance UHMWPE’s mechanical performance is superior to common HDPE. Not only it has outstanding impact-resistance, self-lubrication, low coefficient of friction, high-temperature slow-flow change-resistance as well as stress crack resistance, high temperature creep, low coefficient of friction, but also it has great self lubricating, excellent chemical resistance, fatigue resistance, noise damping resistance, radiation resistance and so on. Its applicable temperature is 100~110℃ to minus 269℃. With the density of 0.935g/cm3,UHMWPE product with 200 million molecular has strong crack and stretch resistance of 40MPa. Its stretch ratio of crack is 350%, the volume of bending elasticity is 600MPa., cantilever breach is unbreakable to impact, and waste volume (MPC method) is 20mm。 Application UHMWPE is able to substitute carbon steel, stainless steel, bronze and other material applied in industries such as textile, paper-making, food-processing machine, transportation, medicine, coal mining, chemistry etc. Set textile industry for example, UHMWPE can be applied as impact-resistant parts of shuttle-sending device, picking stick, gear, coupling, sweeping flower poles, buffer blocks, eccentric blocks, rod bushings, swing back beam and so on. Also it can be applied as crate covers, water-sh***ing sheet, compressing parts, tie-in, sealed axis of tran***ission machine, jockey roller, sh***er, filter etc in paper-making industry whereas worked as a filler container, filler garage and lining plate of slide notch in transportation industry. UHMWPE can be processed as parts and components of all kinds of machinery, including gears, worm gear, worm, bearings of food machinery; pumps, valves, baffle, plate of chemical industry; heart valves, short-shaped surgical parts, artificial joints and birth control implants in Medical industry;. skating floor, rolling path for bowling, snowboarding, motor sled parts for sports industry; also it can be manufactured bulletproof vests, aircraft seats, shipping, fishing, rope and so on when processed as high modulus fiber. The application of UHMWPE is as wide as polyfluortetraethylene and polyamide. The friction-resistance of carbon steel can barely compare with UHMWPE while making it into gears, bearings, bearings, star wheels, valves, pumps, rails, sealing packing, equipment, lining, ***ooth change plates, artificial joints, etc. , fiber for bullet-proof vests, ropes and so on. Though ultra-high molecular weight polyethylene possesses so many excellent properties, such an excellent engineering plastic was barely known. It was mainly because of inadequate processing methods of melt characteristics of UHMWPE in the past. The techniques were basically stuck in suppression of a sintering process which was out of time. However, with the continuous developing of processing technology of UHMWPE, its products h***e been applied successfully in many fields recently.