柔性结构滚筒的特长:

自从二十世纪六十年 发钢丝胶带之后,胶带输送机迎来大容量、长距离输送的时代,为了满足大输送量的要求,经反复研究试验,***终将滚筒结构从钢性结构转换为柔性结构。

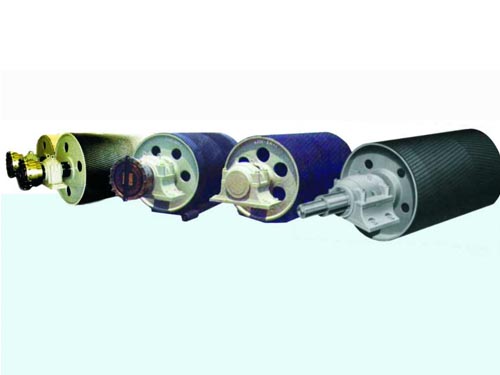

柔性结构滚筒从外观看与刚性结构滚筒基本相同,但是其结构上有着本质的区别,柔性结构滚筒允许滚筒在许用应力范围内产生绕曲弯形,用以吸收一部分动能,缓和局部应力集中,进而提高滚筒整体的疲劳强度,延长使用寿命。我公司制造的柔性结构滚筒使用寿命可确保连续运转六年以上。

柔性结构滚筒的设计要点:

滚筒转动时产生的弯矩和扭矩,特别是交变动载荷作用在滚筒上,致使滚筒受力非常复杂。因此,设计时必须***计算疲劳强度。

Features of Flexible Structure Pulleys

Since the development of steel wire belt in the 60 s of the 20th century, belt conveyor has come into the age of large capacity and long distance carrying. In order to meet the needs of large capacity carrying, pass through research and test time after time, we change the pulley from rigid structure to flexible structure.

The appearance of rigid structure pulleys and flexible structure pulleys are basically similar. but their inner structure are absolutely different. For flexible structure pulleys, flexibility distortion is allowed in the field of allowable stress to absorb partial kinetic energy, relax local stress concentration, and accordingly enhance the whole fatigue intensity of pulleys and extend life-span. It can ensure of more than six years of continuous operation.

Design Essentials ot Flexible Structure Pulleys

On account of bending moment and torque produced from the running of pulleys, especially the alternant fluctuant loads acting on pulleys. the composition of force put on pulleys is very complicated .Therefore, the fatigue intensity must be accurately calculated during the process of design.