Introduction

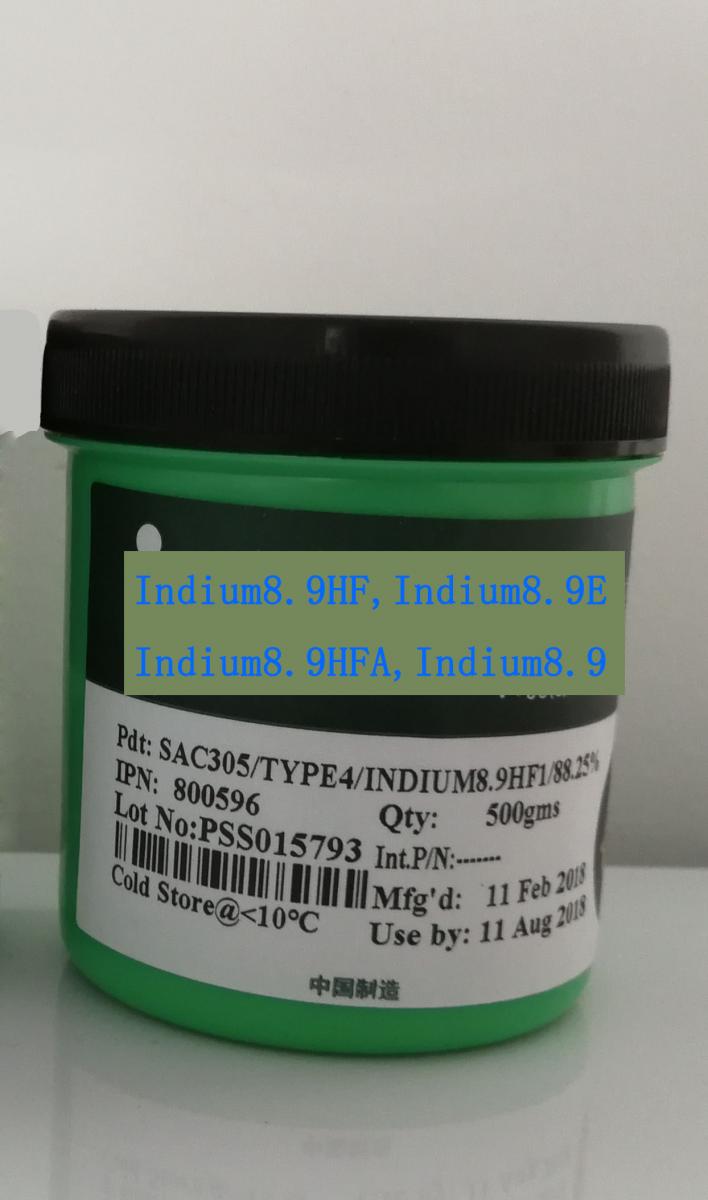

Indium8.9HF-1 is an air reflow, no-clean solder paste. Indium8.9HF-1 offers unprecedented stencil print transfer efficiency to work in the broadest range of processes. In addition, the high probe testability of Indium8.9HF-1 minimizes false failures in ICT.

Alloys

Indium Corporation manufactures low-oxide spherical powder composed of a variety of Pb-free alloys that cover a broad range of melting temperatures. This document covers Type 4 and Type 3 powder as standard offerings with SAC alloys. The metal percent is the weight percent of the solder powder in the solder paste and is dependent upon the powder type and application. Standard product offerings are detailed in the following table.

Features

• High oxidation barrier to eliminate graping and HIP defects

• Highly probe testable flux residue

• Halogen-free per EN14582 test method

• Excellent print transfer efficiency on 0.4mm pitch CSPs

Compatible Products

• Rework Flux: TACFlux®089HF, TACFlux®020B

• Cored Wire: CW-807

• W***e Flux: WF-9945, WF-9958

Note: Other products may be applicable. Please c***ult one of Indium Corporation’s Technical Support Engineers.

Cleaning

Indium8.9HF-1 is designed for no-clean applicati***, however the flux can be removed if necessary by using a commercially ***ailable flux residue remover.

Stencil Cleaning is best performed using isopropyl alcohol (IPA) as a solvent. Most commercially ***ailable non-water-based stencil cleaners work well.

Printing

Stencil Design:

Electroformed and laser cut/electropolished stencils produce the best printing characteristics among stencil types. Stencil aperture design is a crucial step in optimizing the print process. The following are a few general recommendati***:

• Discrete components — A 10-20% reduction of stencil aperture has significantly reduced or eliminated the occurrence of mid-chip solder beads. The “home plate” design is a common method for achieving this reduction.

• Fine pitch components — A surface area reduction is recommended for apertures of 20 mil pitch and finer. This reduction will help minimize solder balling and bridging that can lead to electrical shorts. The amount of reduction necessary is process dependent (5-15% is common).

• For optimum transfer efficiency and release of the solder paste from the stencil apertures, industry standard aperture and aspect ratios should be adhered to.